Welcome to the world of Modular Plant Systems. Construction of modularized plant system has become a popular choice of design. Especially in heavy process industries common to the Oil & Gas and Petrochemical Sector. Generally, such modularizations are used for compact steel frameworks commonly called “skids”. For example when equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted. A complete system may comprise a single skid or a number of skids to form a bigger and sophisticated processing system.

Continue readingSmart DBB Valve Technology

DBB Valves: Traditional installations of DBB Valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges. There are many steps to consider when completing the installation process. In total, there can be as many as 41 steps required for a traditional installation of DBB valves setup.

Continue readingOSHA Standards – Occupational health and safety

Safety requirements in the process industry are extremely high. In some plants, especially in processes, involving flammable liquids or toxic gases, such a leakage can lead to risks to the plant but much important to the personnel – Especially for engineers with focus on maintenance and facility. The DBB Valves made by AS-Schneider provides an added value for all fields of application: https://taurusdbbvalves.com/features/

Continue readingCompact DDB Valves for Modular Plant Systems

Construction of modularized plant system has become a popular choice of design in heavy process industries like the Oil/Gas and Petrochemical Sector. Modularization is where equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted on a compact steel framework, commonly called “skids”.

Continue readingCompact Double Block & Bleed vs. Conventional Installations

Double block and bleed valve systems are conventional installations for most End-Users in the Oil and Gas industry. Conventional installations of DBB valve systems have become a normal practice and can even be found on offshore platforms.

The installation of DBB valve systems is a time consuming process that can negatively impact employees and their work production. The normal process of this type is baded on:

Using two 6” 1500 class ball valve with all the additional materials,

Long and comlex installation process (up to a 41 steps)

Huge amount of material (weight of 2,645 lb(s) = 1200 kg

Important Facts about Fire Safe Standards

Reliable fire protection is essential for industrial valves in industries with sensitive applications. Because of the dangers that come within installations in the oil and gas, chemical, and petrochemical industries, the valves used must guarantee a reliable and safe shut-off in case of fire.

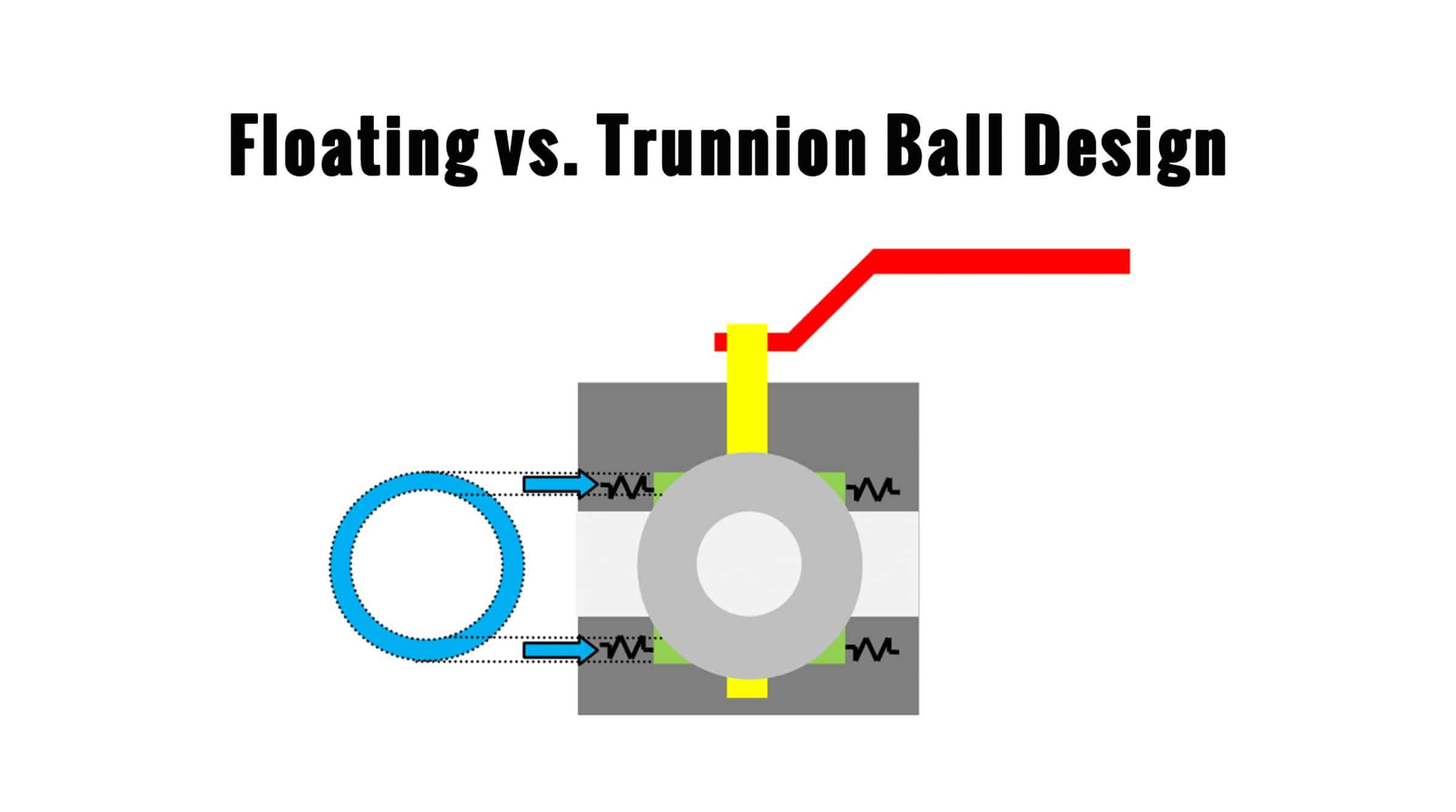

Continue readingDBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

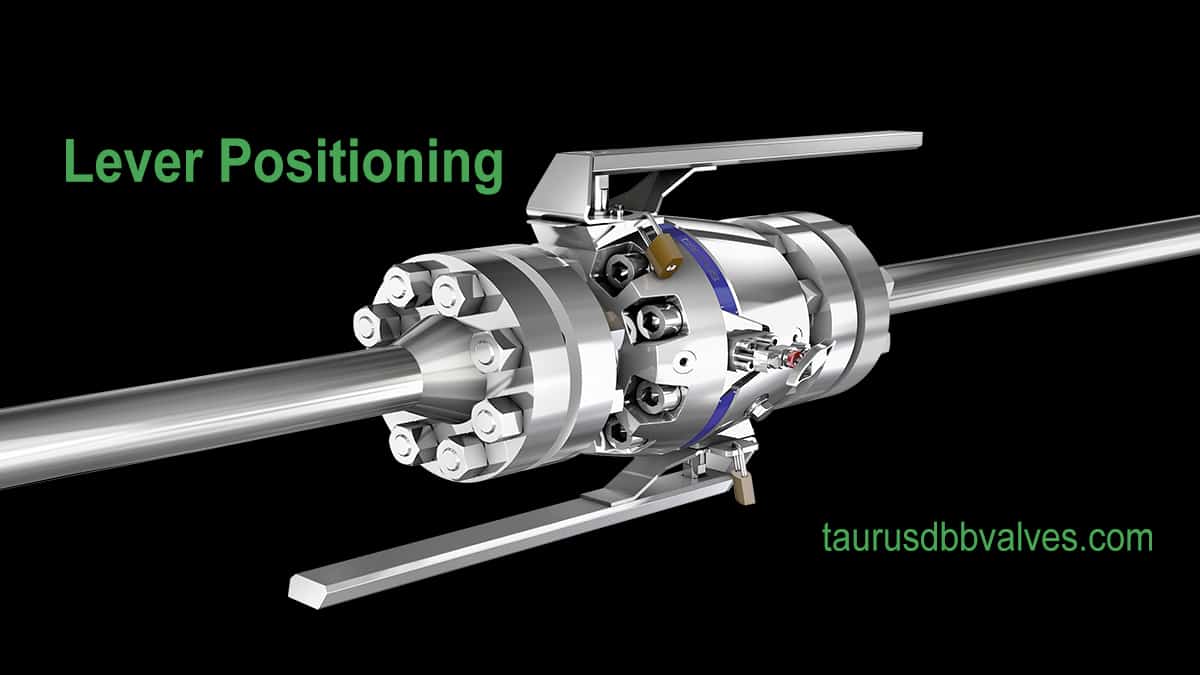

How the position of levers can influence the usability of DBB Valves

Several Ball Valve basic designs are common and therefore a lot of different solutions are available on the market. Especially the position / orientation of the levers have an enormous influence on the usability of the valve, when used in horizontal installations. The following pictures are showing two different options.

Continue readingCost Savings Through Better Performance during Installation and in Use

Traditional installations of Double Block & Bleed (DBB) valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges.

Continue readingDBB Valves in severe service applications

Having worked on many projects in the past, it seemed that many piping engineers tend to stereotype the term “severe service” on their valve requirements.

In a given process or system, only few can be considered as such, but they are the ones that pose the greatest design challenge. Each type of valve (and there are many of them) has several parameters to consider.

Continue reading