Oil and gas pipelines often pass over long distances through rough environments. They face exposure to temperature variations and other weather influences. The technology used must meet the highest quality standards. Manufacturers always have to ensure a smooth distribution of liquids and gases. Proper distribution helps them to avoid any leakages.

Continue readingThe Imperative of Fire Safe Testing!

I often hear people saying “Metal seated valves with graphite sealing don’t need to be fire safe tested, as all the components are fire resistant”.

To be honest, starting my career as a valve engineer, I was convinced, that this common understanding is true – until I did fire safe tests on my own for our Monoflange Series, many years ago. Even after this long period of time I remember very well, when we did the pre-tests. I looked very surprised, when the valve seat was leaking during the firing of the valve.

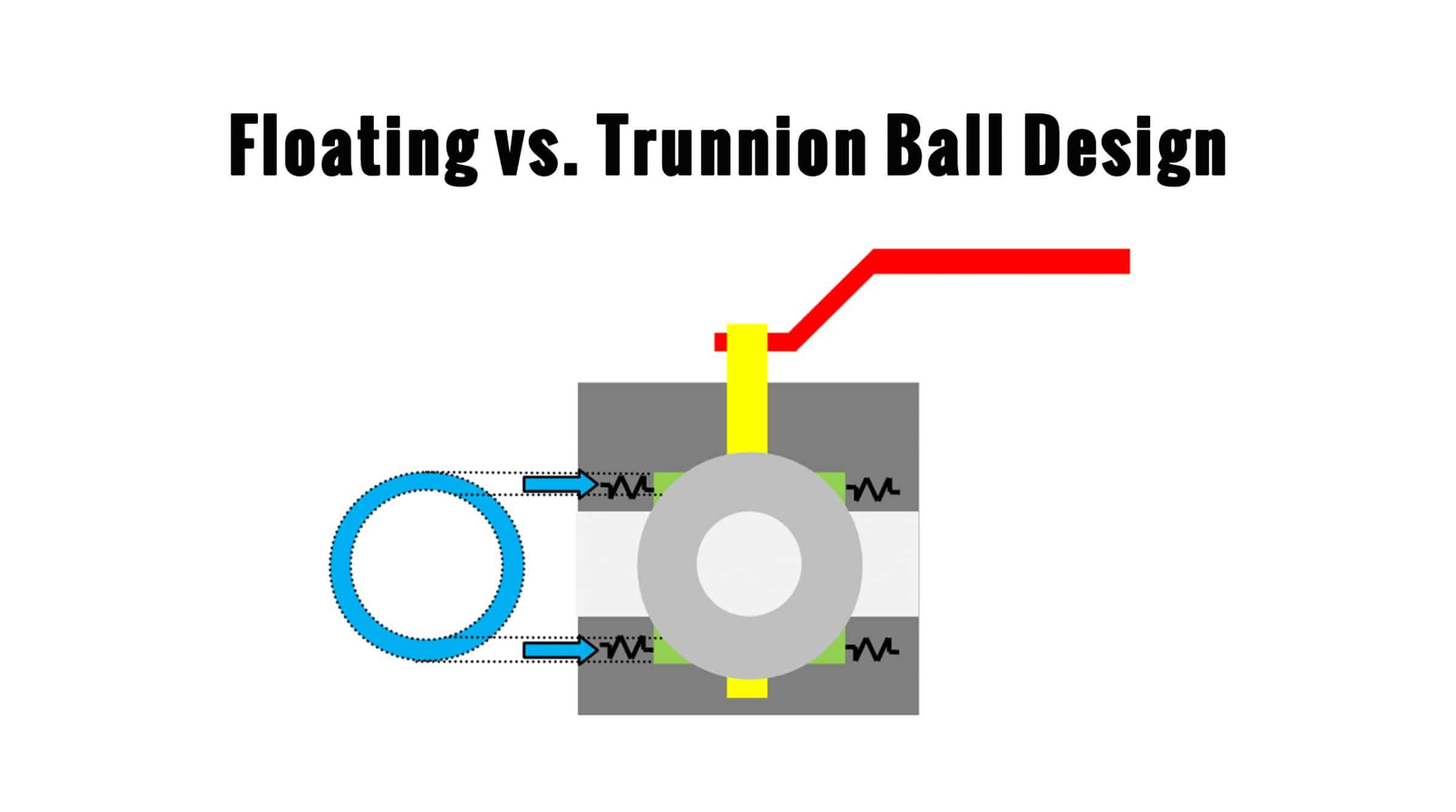

DBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

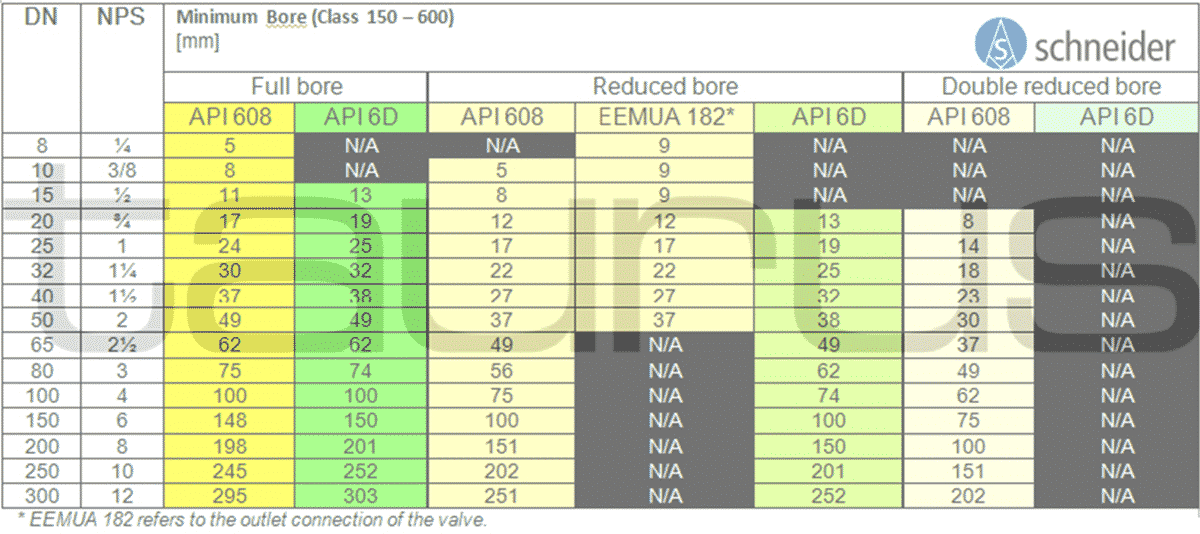

What does Full Bore stand for?

There has always been a lot of confusion and misunderstanding when it comes to Full Bore and Reduced Bore terminology. Let me try to explain some interesting facts. For example, DBB Valves are developed mainly for the use in the Oil and Gas sector. In this industry, the relevant design standards are ….

Continue readingReplace a single ball valve by a Double Block & Bleed

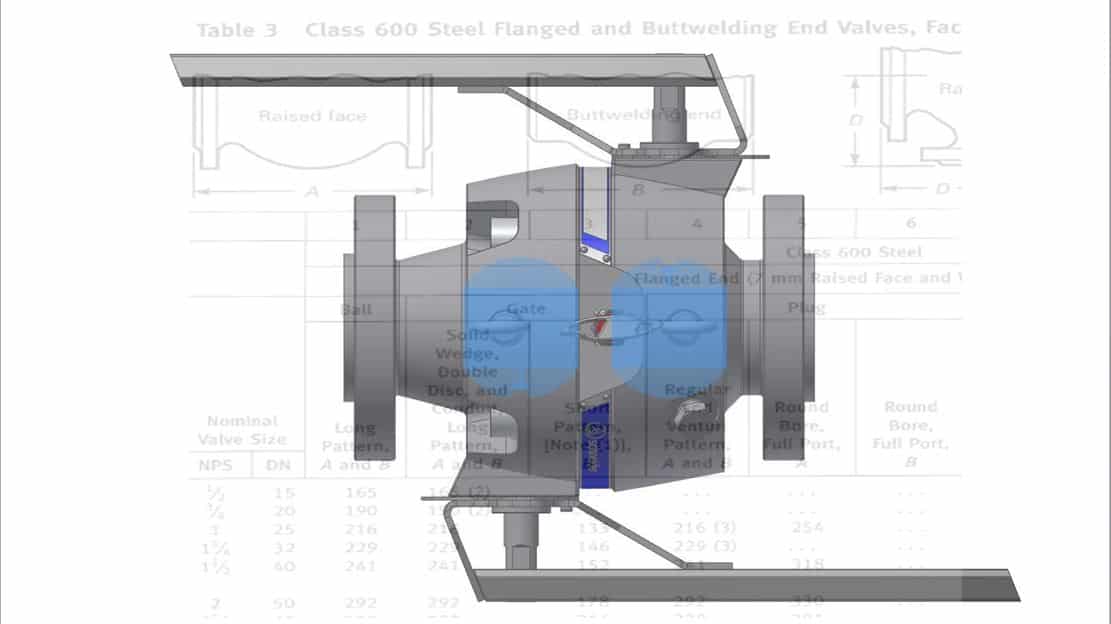

When creating the design specification for our Taurus Series we came along the point ‘face to face’ dimensions. Immediately some colleague said “ASME B16.10 and EN 558 – but same length as a single ball valves for the Taurus DBB with 2 balls and a bleed in between?”

Well, we discussed that there might be a possibility to achieve this goal and we listed some values and benefits we could offer to our customers with such a short face to face dimension:

The major benefit would be that the new Double Block & Bleed (DBB) Pipeline Ball Valve (Taurus-Series) has the same face-to-face dimension as a single block ball valve. The length of a single block ball valve is specified in ASME B16.10 and APl 6D. As a consequence the valve can easily be installed into an existing pipeline without the need for any re-work on the pipeline.

Continue readingHow tight is your Valve Seat?

When people ask me, how tight our valve seats are, I usually get an increased heart rate and I most would like to say “Oh yes, they are very tight”.

But fun aside ….

Please note that I’m not talking about external tightness (stem sealing and body sealing), as there are already several accepted standards like ISO 15848-1, API 622, API 624, etc. which describe the evaluating of the valve design with respect to fugitive emissions. Those standards where driven by the legal environmental requirements and do not consider the internal tightness of the valve.

When talking about valves seat tightness, we have to differ between just a maximum leak rate of a production test and a seat performance test.

Continue reading“Fire Safe Approved” vs. “Fire Safe by Design”

During the last years I recognized, that people sometimes talk about “Fire Safe by Design“. When I was coming across this the first time, I wondered about the meaning of this in detail – Just using metal to metal sealing, graphite sealing or graphite packing?

“Fire safe by Design” is widely used, but to my knowledge there is no common or firm description or rules limiting or qualifying the use of this concept.

Continue reading