DBB Valves: Traditional installations of DBB Valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges. There are many steps to consider when completing the installation process. In total, there can be as many as 41 steps required for a traditional installation of DBB valves setup.

Continue readingImportance of design flexibility for complex requirements

Valve customization is adapting to customers’ needs in regards to changing body materials, port connections, testing requirements, and various combinations of different assembly types. Being open to different design ideas, and accepting the challenge the customer set forth. As a valve manufacturer we strive to impress our customers with our many years of experience in building valves. Every day we continue to receive new design request from our customers for complex requirements. Since we have over 140 years in customizing valves experience, our customer can trust that we are experts in the industry.

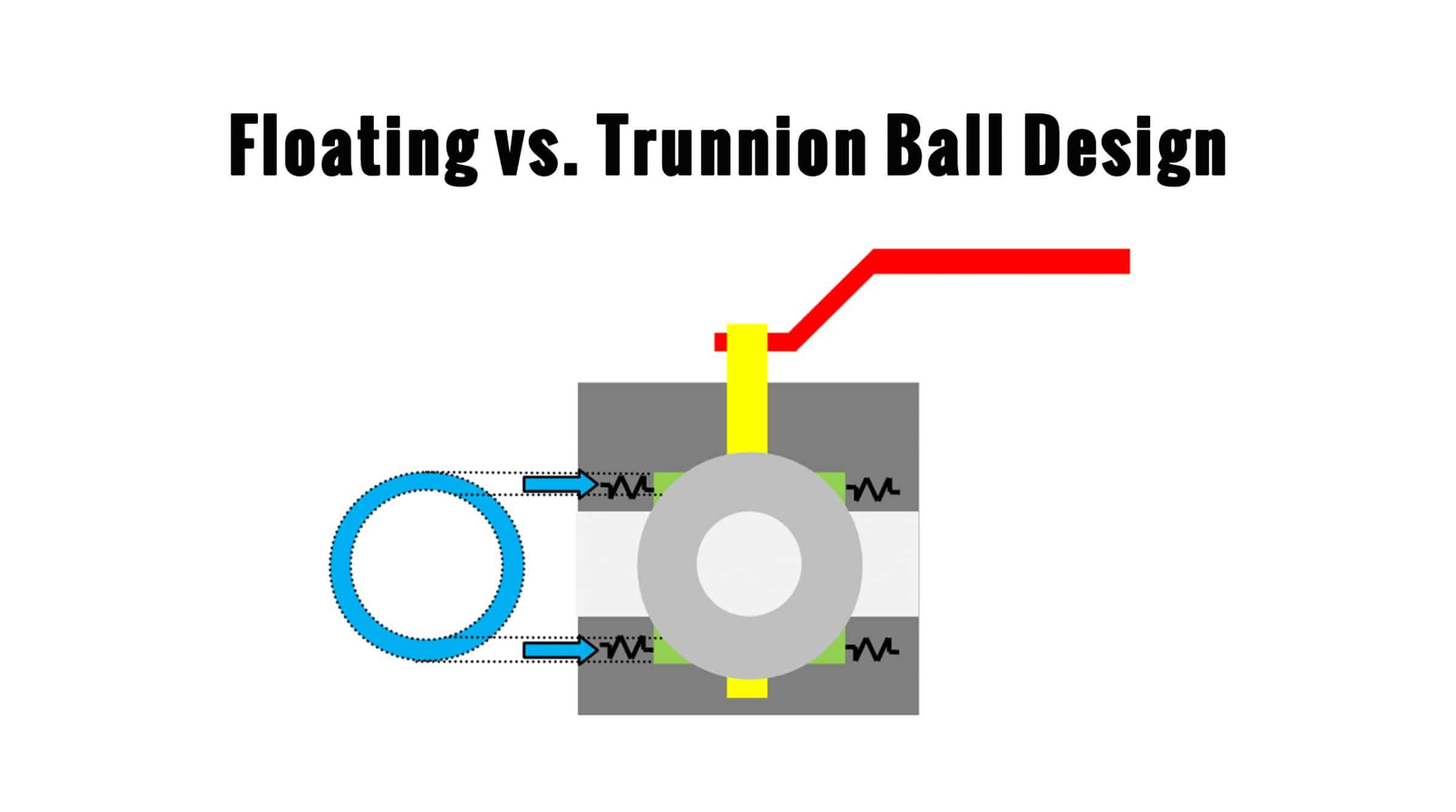

Continue readingDBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.