Hard at work in the pipeline

Discover the Taurus Features

Feature overview

Standards & Pressure

Design & Materials

-

Full bore

Meets the minimum bore requirements according to API 6D / ISO 14313, Table 1 -

Reduced bore

One size below nominal size of valve with bore according to API 6D / ISO 14313, Table 1 -

Pressure class

150 to 2,500

-

Fire safe

in accordance to API 607 and ISO 10497 -

Compliant to NACE

MR0175 and ISO 15156 -

Factory tested

in accordance with ASME B16.34, API 6D / ISO 14313, ISO 5208 - Manufactured in accordance with the pressure equipment directive

- Standard materials of construction Stainless Steel 316, Duplex and forged Carbon Steel A105/LF2.

-

Ball seat material

PTFE, Devlon, PEEK or Metal Seated -

Stem seal material

FKM or HNBR. RGD resistant (Rapid Gas Decompression) or Graphite. -

Design variations

– Stem design ensures the anti-blow-out function. – Anti-static design used to reduce the static charge generated on the ball due to friction.

-

Weld inlay

Seat pocket and seal area overlay on request -

Bi-directional

Floating and trunnion ball valves are bi-directional by default. -

Painting

DBB valves are available with any kind of adequate coating for environmental protection.

ADDED VALUE FOR ALL FIELDS OF APPLICATION

Purchase & Supply Chain

- Base your purchase decision on TCO/TVO calculations rather than simply lowest costs

- Access to valuable information to base your selection of vendors on

- Stay updated about latest developments when it comes to DBB valve technology

Piping

- We understand your focus on getting best quality products installed on your pipelines. Read about best practices and latest trends.

- Get updates about standards and regulations

- Stay updated about the latest developments when it comes to DBB valve technology

Design

- Make your life easier with free access to 2D and 3D models

- Access to technical documentation and data sheets

- Get updates about standards and regulations

- Stay updated about the latest developments when it comes to DBB valve technology

Health Safety & Environment

- Safety is our utmost priority – stay on top of latest developments when it comes to safety.

- Get updates about environmental standards and regulations such as TA-Luft or ISO 15848

- Stay updated about the latest developments when it comes to DBB valve technology

Maintenance

- We know the pain of maintaining and handling bulky products on the field – stay informed about latest trends and information making your life easier

- Access to valuable infographics and video clips

- Stay updated about the latest developments when it comes to DBB valve technology

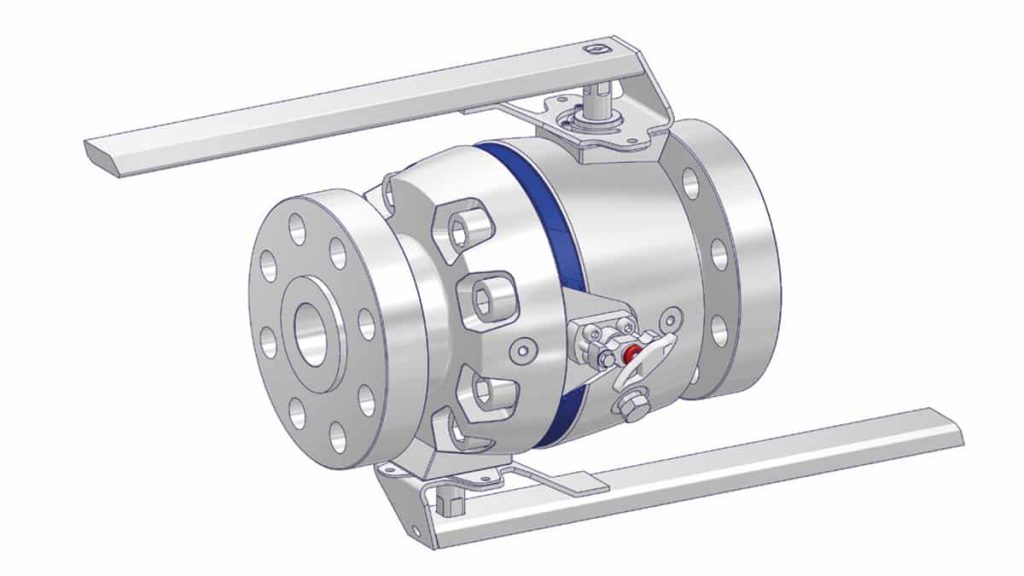

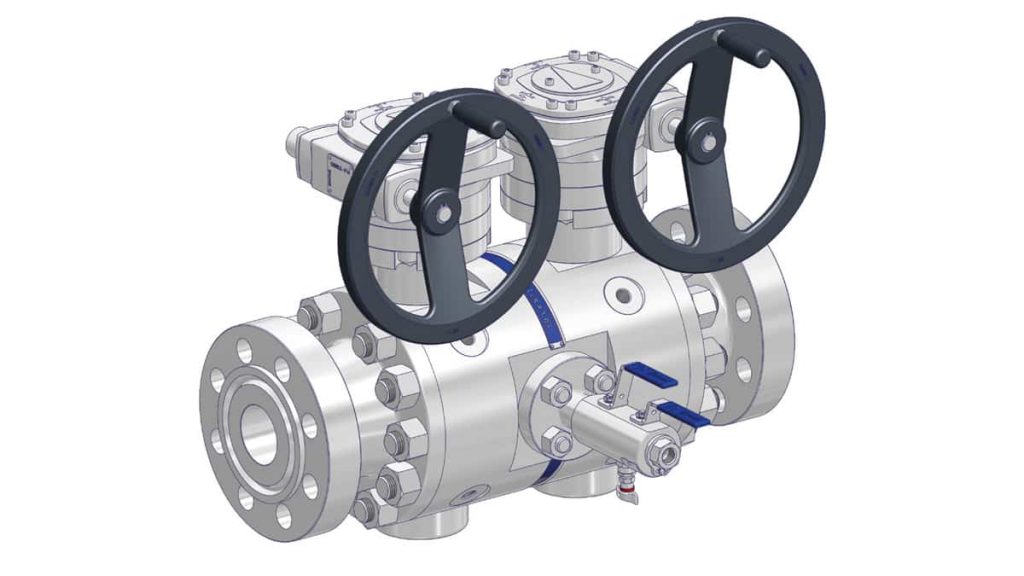

Different Designs

High-quality pieces for every requirement

SIGNIFICANT ADVANTAGES

Reduce your installation and maintenance costs

Compact Assembly

0

Reduced Weight

0

Reduced

Leak Path

Leak Path

0

Space Savings

0

CERTIFICATION & TRACEABILITY

Material test certificates 3.1 according to EN 10204. A unique code is stamped on all relevant components linking them with their material and chemical analysis certificates.

Codes and specifications

Reduce your installation and maintenance costs

| CODE | SPECIFICATION |

|---|---|

| ASME B31.3 | Process Piping |

| ASME B16.34 | Valves – Flanged, Threaded and Welding End |

| ASME B16.5 | Pipe Flanges and Flanged Fittings |

| ASME B16.10 | Face-to-Face and End-to-End Dimensions of Valves |

| ASME B16.11 | Forged Fittings, Socket Welding and Threaded |

| ASME B16.25 | Buttwelding Ends |

| NACE MR0175 / ISO 15156 | Petroleum and Natural Gas Industries – Materials for use in H2S-containing Environments in Oil and gas Production |

| API 6D / ISO 14313 | Specification for Pipeline Valves Petroleum and Natural Gas Industries – Pipeline Transportation Systems – Pipeline Valves |

| API 598 | Valve Inspection and Testing |

| ISO 5208 | Industrial Valves – Pressure Testing of Metallic Valves |

| API 607 / ISO 10497 | Fire Test for Soft-Seated Quarter Turn Valves Testing of Valves. Fire Type-testing Requirements |

| MSS SP-25 | Standard Marking System for Valves, Fittings, Flanges and Unions |