When I started my career as a valve engineer, one of the first lessons were: Which materials are used for valve components. Didn`t know too much about the details of the different materials, for me, the most strange material at that times was the 316 Series.

Continue readingCompact DDB Valves for Modular Plant Systems

Construction of modularized plant system has become a popular choice of design in heavy process industries like the Oil/Gas and Petrochemical Sector. Modularization is where equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted on a compact steel framework, commonly called “skids”.

Continue readingImportance of design flexibility for complex requirements

Valve customization is adapting to customers’ needs in regards to changing body materials, port connections, testing requirements, and various combinations of different assembly types. Being open to different design ideas, and accepting the challenge the customer set forth. As a valve manufacturer we strive to impress our customers with our many years of experience in building valves. Every day we continue to receive new design request from our customers for complex requirements. Since we have over 140 years in customizing valves experience, our customer can trust that we are experts in the industry.

Continue reading[Interview] Trend Towards Remote Maintenance (de-manning) in the Oil and Gas Sector

Frans and Tim are in frequent exchange about the future of the Oil & Gas Industry. On June 26th, 2017, we have published the transcript of their first discussion on our website. You can read the full transcript “Challenges and Trends in the Oil & Gas Industry” here.

Continue readingThe Imperative of Fire Safe Testing!

I often hear people saying “Metal seated valves with graphite sealing don’t need to be fire safe tested, as all the components are fire resistant”.

To be honest, starting my career as a valve engineer, I was convinced, that this common understanding is true – until I did fire safe tests on my own for our Monoflange Series, many years ago. Even after this long period of time I remember very well, when we did the pre-tests. I looked very surprised, when the valve seat was leaking during the firing of the valve.

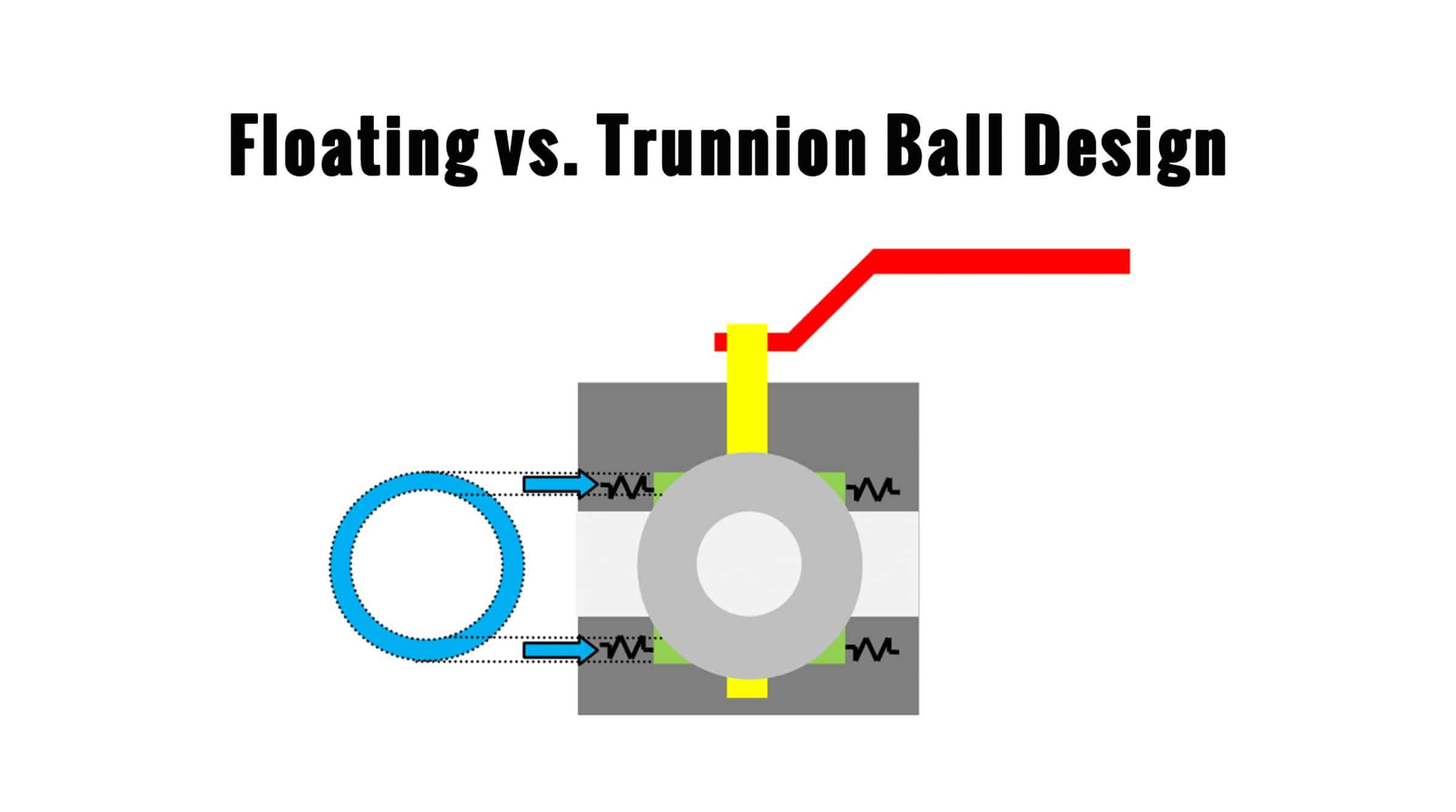

DBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

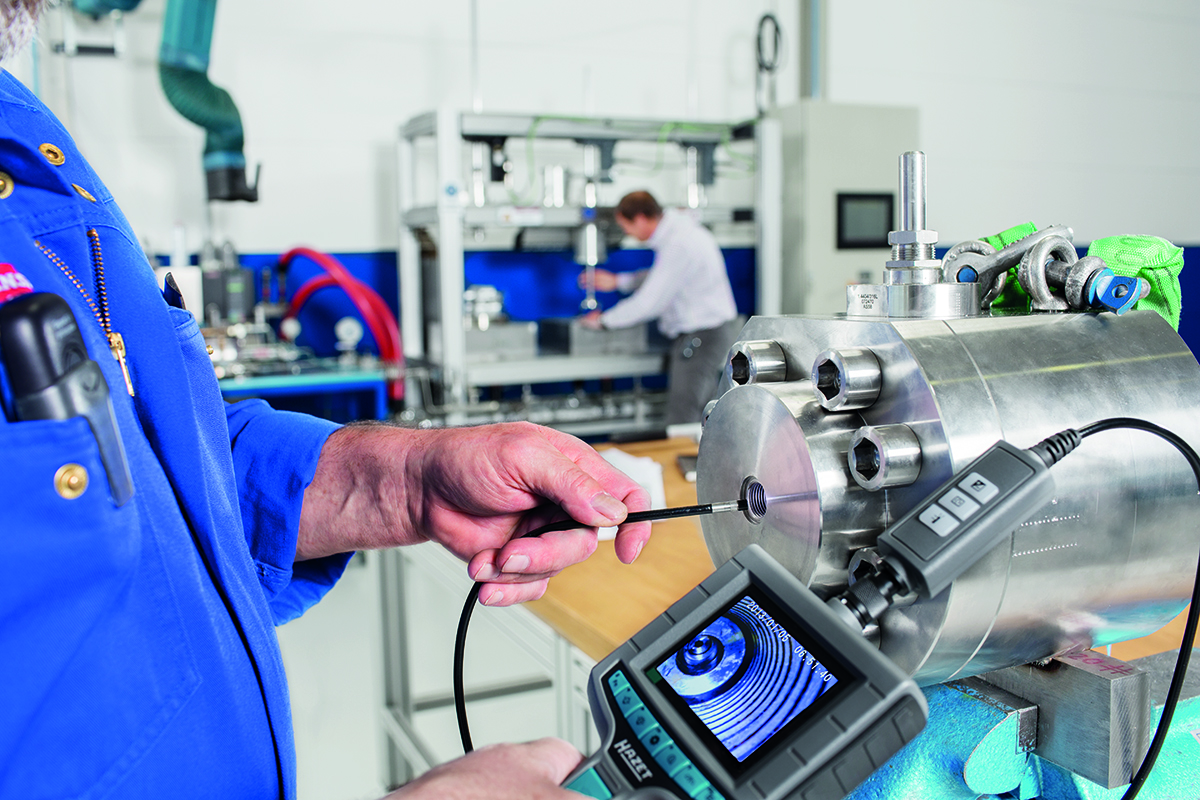

The most important facts of an own Valve Test Center

When I think back 20 years, I nearly cannot imagine how we were able to provide such high quality valves without the means of testing them in such an extensive way like we do this today.

I remember very well the time, when I started at AS-Schneider as a design engineer. Fire Safe Approvals and Fugitive Emission Testing (TA-Luft) had to be done outside the company on a third party test rig. There was no chance to do a pre-testing and it was always very exciting when the third party like TÜV was witnessing the tests. Well, most of the approvals were passed successfully, but I also remember some Type approvals were we failed at the first stage. The disappointment was great and we lost time with the re-design and the second try.

Today we are very glad to operate our TechCenter with 2 Fire Safe test rigs, a fully automated valve test bench, a climate chamber, etc. Once we started our TechCenter, it was so exciting for us to learn what our valves are able to withstand and where they have their limits.

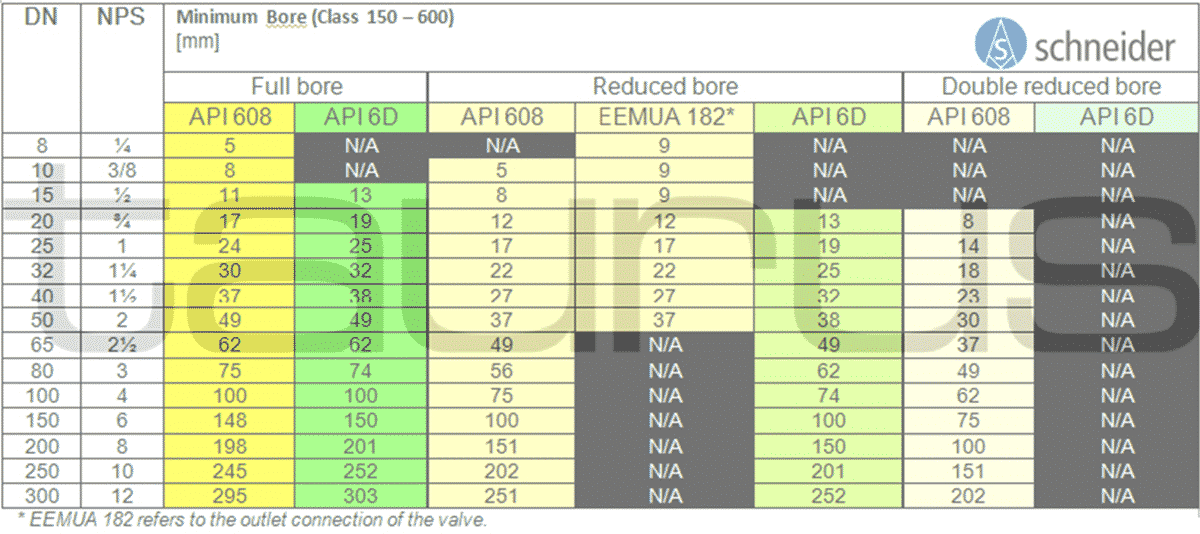

Continue readingWhat does Full Bore stand for?

There has always been a lot of confusion and misunderstanding when it comes to Full Bore and Reduced Bore terminology. Let me try to explain some interesting facts. For example, DBB Valves are developed mainly for the use in the Oil and Gas sector. In this industry, the relevant design standards are ….

Continue readingFugitive Emissions: ISO 15848 vs. TA-Luft

Tracking and limiting Fugitive Emissions has moved into the focus of many countries around the world. Stringent legal requirements force the industry to rethink and use emission-reducing equipment. This sounds very simple, but from my experience there is still misconception when it comes to this subject.

Continue readingDBB Valves in severe service applications

Having worked on many projects in the past, it seemed that many piping engineers tend to stereotype the term “severe service” on their valve requirements.

In a given process or system, only few can be considered as such, but they are the ones that pose the greatest design challenge. Each type of valve (and there are many of them) has several parameters to consider.

Continue reading