Valve customization is adapting to customers’ needs in regards to changing body materials, port connections, testing requirements, and various combinations of different assembly types. Being open to different design ideas, and accepting the challenge the customer set forth. As a valve manufacturer we strive to impress our customers with our many years of experience in building valves. Every day we continue to receive new design request from our customers for complex requirements. Since we have over 140 years in customizing valves experience, our customer can trust that we are experts in the industry.

Continue readingThe Advantantage of using a compact DBB Valve

In the Oil/Gas industry, although it has become very common, the use of a compact Double Block & Bleed (DBB) valve for pressure energy isolation is still not applied or adopted across the board. I have experienced a few times wherein the use of a DBB valve for process isolation is more of an option rather than a design requirement.

Continue readingCompact Double Block & Bleed vs. Conventional Installations

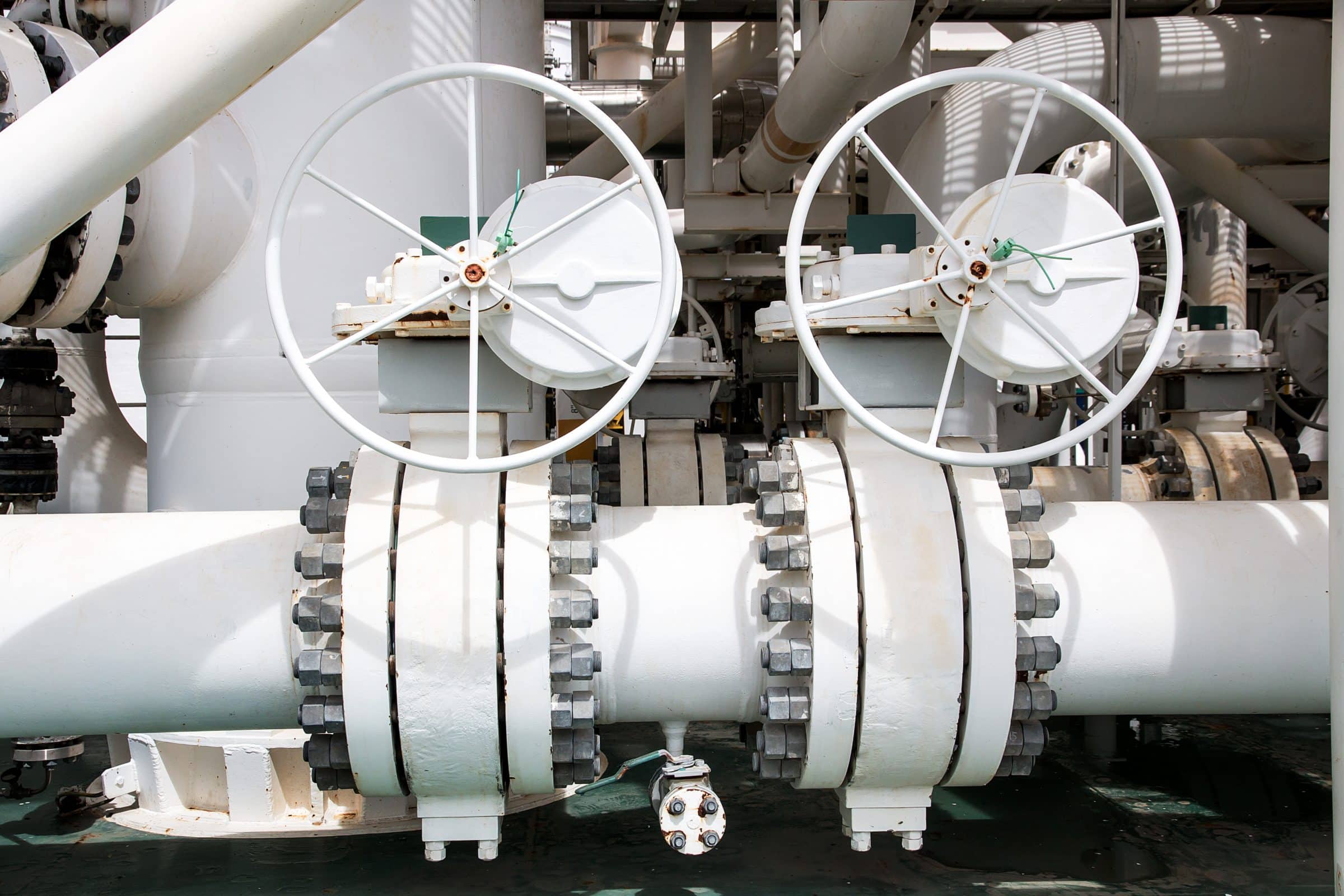

Double block and bleed valve systems are conventional installations for most End-Users in the Oil and Gas industry. Conventional installations of DBB valve systems have become a normal practice and can even be found on offshore platforms.

The installation of DBB valve systems is a time consuming process that can negatively impact employees and their work production. The normal process of this type is baded on:

Using two 6” 1500 class ball valve with all the additional materials,

Long and comlex installation process (up to a 41 steps)

Huge amount of material (weight of 2,645 lb(s) = 1200 kg

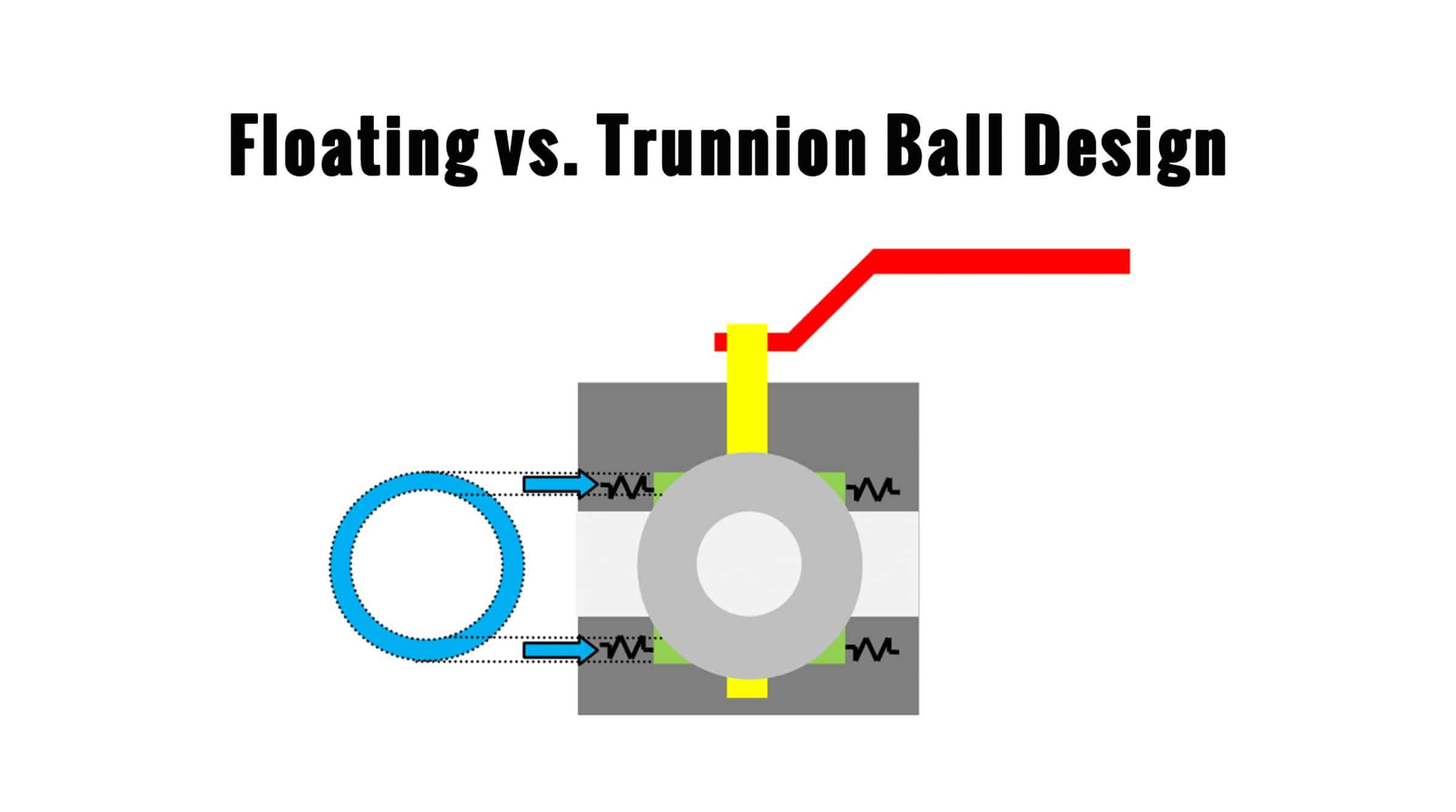

DBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

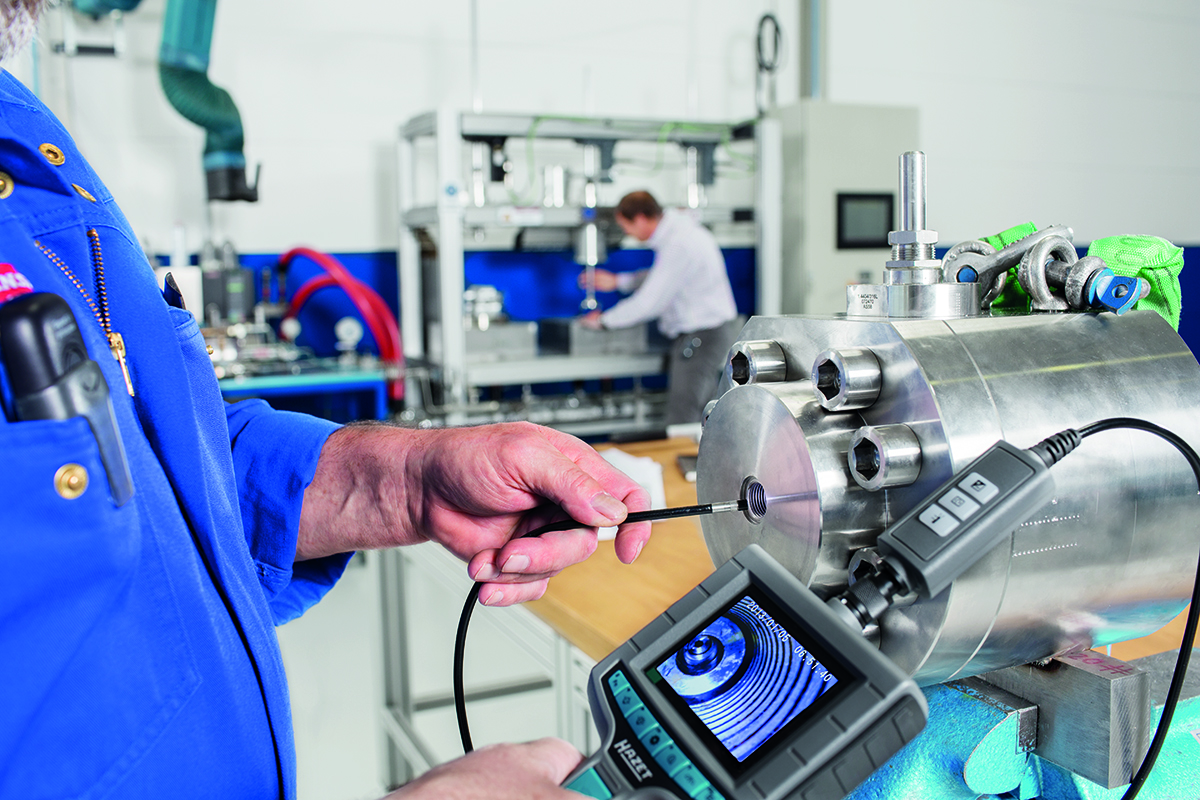

The most important facts of an own Valve Test Center

When I think back 20 years, I nearly cannot imagine how we were able to provide such high quality valves without the means of testing them in such an extensive way like we do this today.

I remember very well the time, when I started at AS-Schneider as a design engineer. Fire Safe Approvals and Fugitive Emission Testing (TA-Luft) had to be done outside the company on a third party test rig. There was no chance to do a pre-testing and it was always very exciting when the third party like TÜV was witnessing the tests. Well, most of the approvals were passed successfully, but I also remember some Type approvals were we failed at the first stage. The disappointment was great and we lost time with the re-design and the second try.

Today we are very glad to operate our TechCenter with 2 Fire Safe test rigs, a fully automated valve test bench, a climate chamber, etc. Once we started our TechCenter, it was so exciting for us to learn what our valves are able to withstand and where they have their limits.

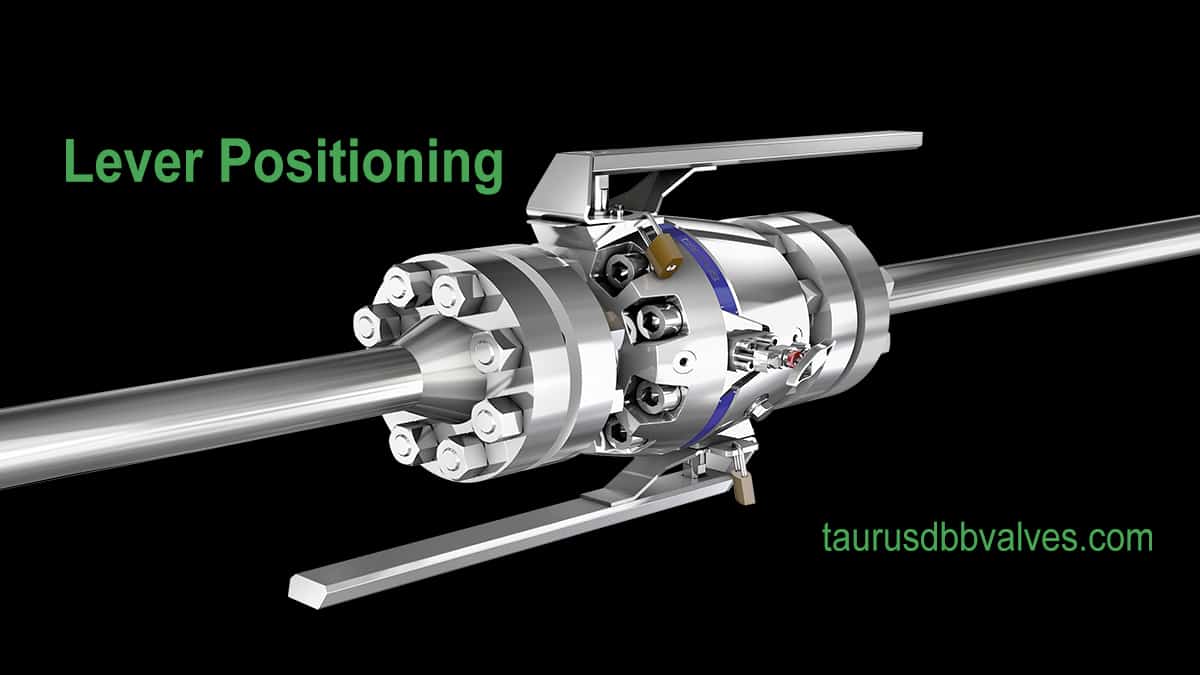

Continue readingHow the position of levers can influence the usability of DBB Valves

Several Ball Valve basic designs are common and therefore a lot of different solutions are available on the market. Especially the position / orientation of the levers have an enormous influence on the usability of the valve, when used in horizontal installations. The following pictures are showing two different options.

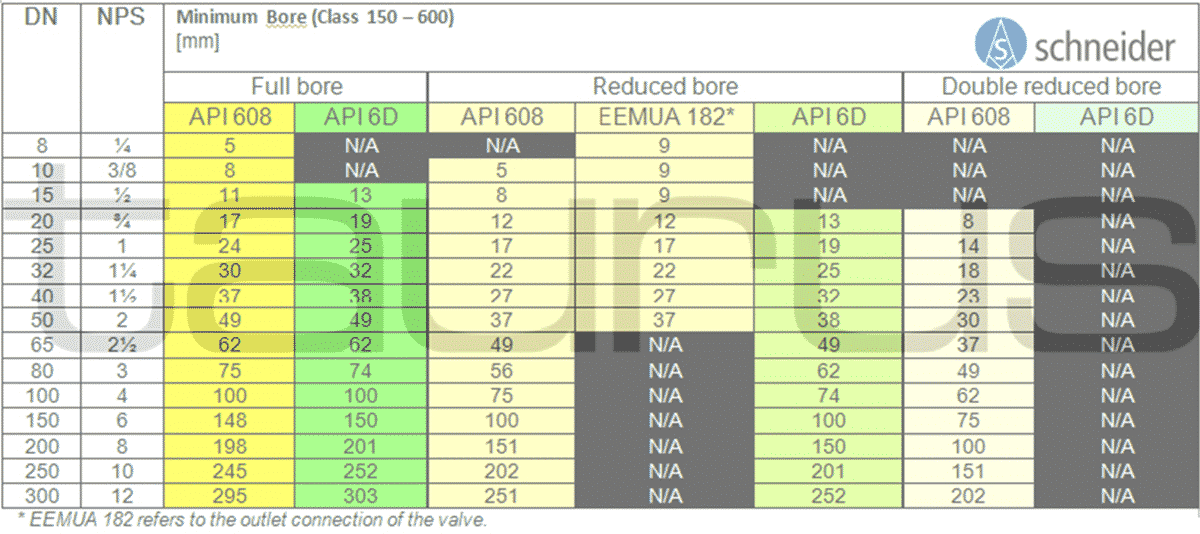

Continue readingWhat does Full Bore stand for?

There has always been a lot of confusion and misunderstanding when it comes to Full Bore and Reduced Bore terminology. Let me try to explain some interesting facts. For example, DBB Valves are developed mainly for the use in the Oil and Gas sector. In this industry, the relevant design standards are ….

Continue readingFugitive Emissions: ISO 15848 vs. TA-Luft

Tracking and limiting Fugitive Emissions has moved into the focus of many countries around the world. Stringent legal requirements force the industry to rethink and use emission-reducing equipment. This sounds very simple, but from my experience there is still misconception when it comes to this subject.

Continue readingDBB Valves in severe service applications

Having worked on many projects in the past, it seemed that many piping engineers tend to stereotype the term “severe service” on their valve requirements.

In a given process or system, only few can be considered as such, but they are the ones that pose the greatest design challenge. Each type of valve (and there are many of them) has several parameters to consider.

Continue readingReplace a single ball valve by a Double Block & Bleed

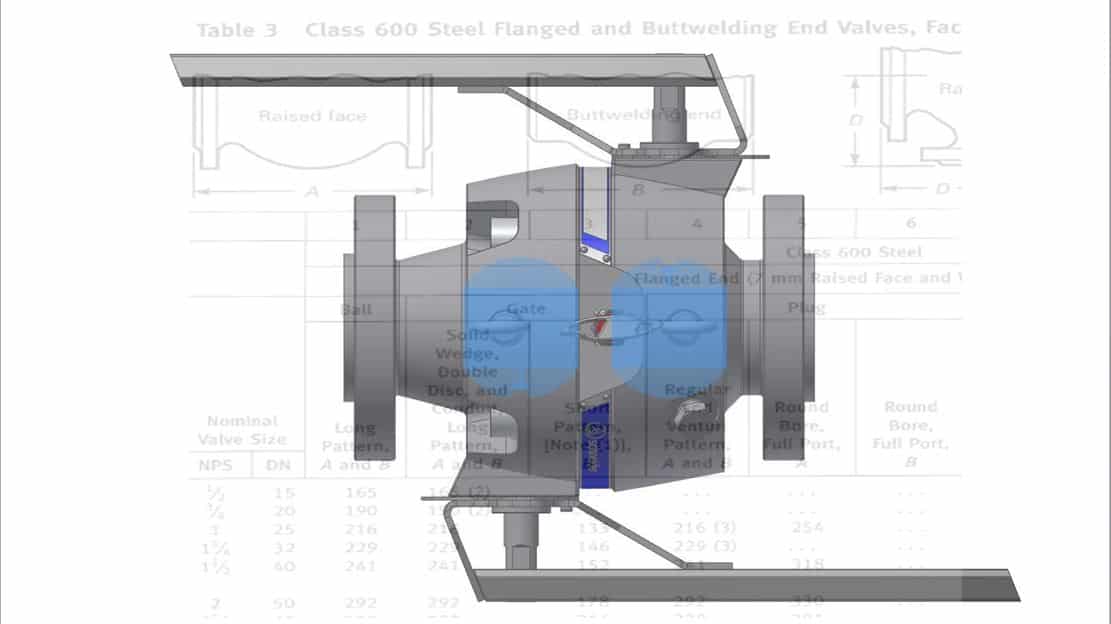

When creating the design specification for our Taurus Series we came along the point ‘face to face’ dimensions. Immediately some colleague said “ASME B16.10 and EN 558 – but same length as a single ball valves for the Taurus DBB with 2 balls and a bleed in between?”

Well, we discussed that there might be a possibility to achieve this goal and we listed some values and benefits we could offer to our customers with such a short face to face dimension:

The major benefit would be that the new Double Block & Bleed (DBB) Pipeline Ball Valve (Taurus-Series) has the same face-to-face dimension as a single block ball valve. The length of a single block ball valve is specified in ASME B16.10 and APl 6D. As a consequence the valve can easily be installed into an existing pipeline without the need for any re-work on the pipeline.

Continue reading