I often hear people saying “Metal seated valves with graphite sealing don’t need to be fire safe tested, as all the components are fire resistant”.

To be honest, starting my career as a valve engineer, I was convinced, that this common understanding is true – until I did fire safe tests on my own for our Monoflange Series, many years ago. Even after this long period of time I remember very well, when we did the pre-tests. I looked very surprised, when the valve seat was leaking during the firing of the valve.

[Interview] – Smart Technology in the Valve Sector

Juan is a Sr. Consultant with over 25 years of experience in the upstream O&G Industry working at different levels and capacities from Lead Engineer to Management, holding a successful record of accomplishments. Experienced in Advance Drilling, Production, and Marine Systems and have participated extensively in Rig (JU & Floaters) Design and Construction, with In-Depth involvement from Concept Development to Commissioning and Delivery of over 20 new Offshore Rigs, in addition to several life enhancement, upgrades, and refurbishment projects.

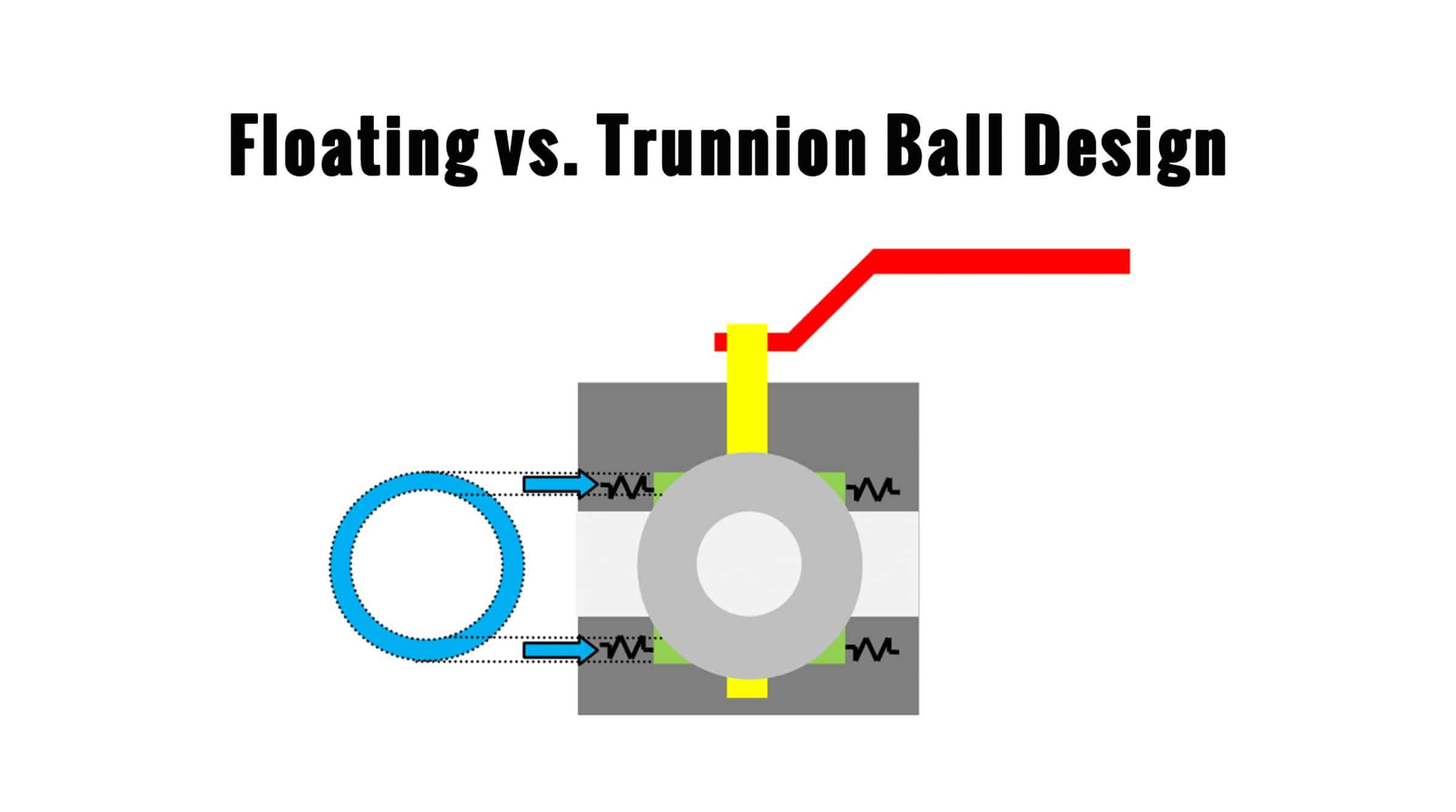

Continue readingDBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

[Interview] Challenges and Trends in the Oil & Gas Industry

Interview: Frans Martens, Industry Expert, reports on the develompent of the Oil & Gas Industry. Frans has 35 years of experience in both the upstream and well as the downstream parts of a major oil and gas company, working in the Netherlands, Germany and Oman. His knowledge and experience cover field devices, telemetry, process control systems and final elements such as control valves and actuators for on/off valves. Frans has been involved in standardization work, vendor and product acceptance work, the development and delivery of training courses. As of January 2017, Frans is self-employed as an independent consultant to the industry. Frans holds a bachelor’s degree in electrical engineering and telecommunication.

Continue readingImprove Safety – Upgrade to DBB Valves

It is very easy to upgrade your existing Single Isolate Ball Valve installation. Simply use a DBB with Face-to-Face and End-to-End dimensions acc. to ASME B16.10.

Use a DBB Dual Ball Design improve Safety and Process Reliability. Here is a simple infographic to illustrate the interchangeability using ASME B16.10 dimensions:

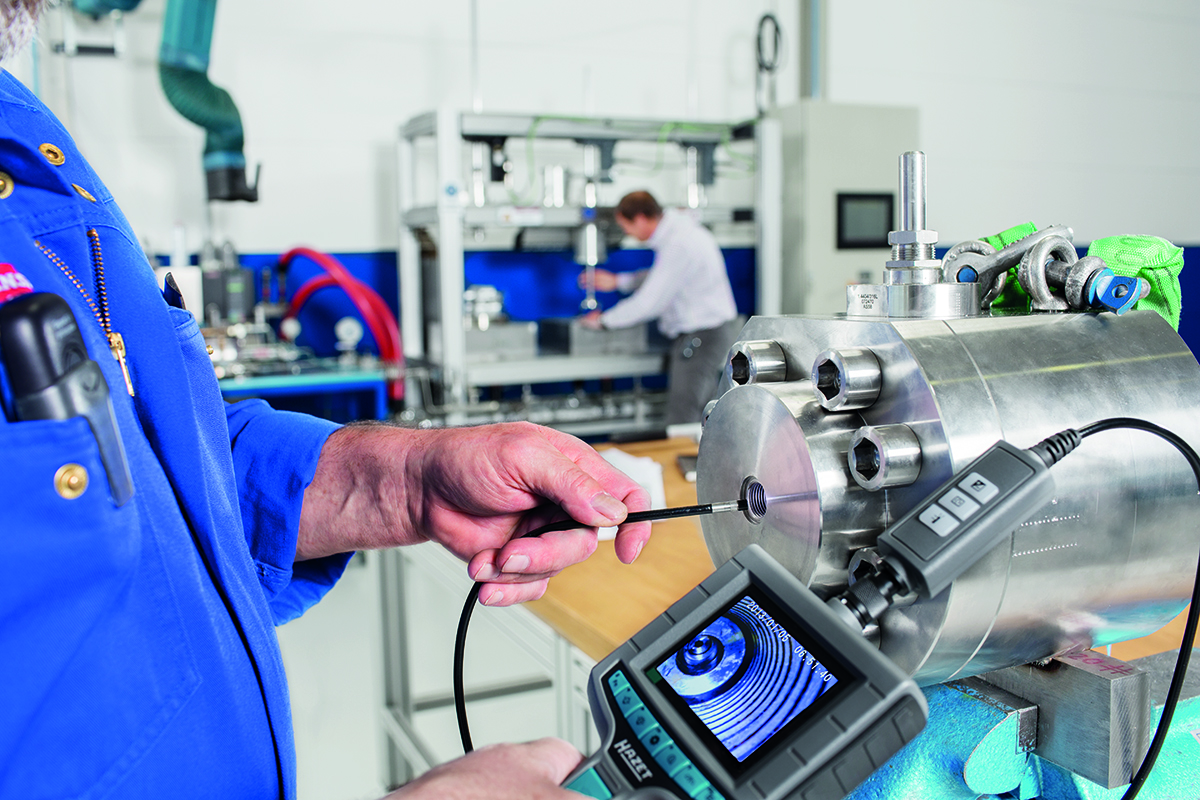

Continue readingThe most important facts of an own Valve Test Center

When I think back 20 years, I nearly cannot imagine how we were able to provide such high quality valves without the means of testing them in such an extensive way like we do this today.

I remember very well the time, when I started at AS-Schneider as a design engineer. Fire Safe Approvals and Fugitive Emission Testing (TA-Luft) had to be done outside the company on a third party test rig. There was no chance to do a pre-testing and it was always very exciting when the third party like TÜV was witnessing the tests. Well, most of the approvals were passed successfully, but I also remember some Type approvals were we failed at the first stage. The disappointment was great and we lost time with the re-design and the second try.

Today we are very glad to operate our TechCenter with 2 Fire Safe test rigs, a fully automated valve test bench, a climate chamber, etc. Once we started our TechCenter, it was so exciting for us to learn what our valves are able to withstand and where they have their limits.

Continue readingHow the position of levers can influence the usability of DBB Valves

Several Ball Valve basic designs are common and therefore a lot of different solutions are available on the market. Especially the position / orientation of the levers have an enormous influence on the usability of the valve, when used in horizontal installations. The following pictures are showing two different options.

Continue readingCost Savings Through Better Performance during Installation and in Use

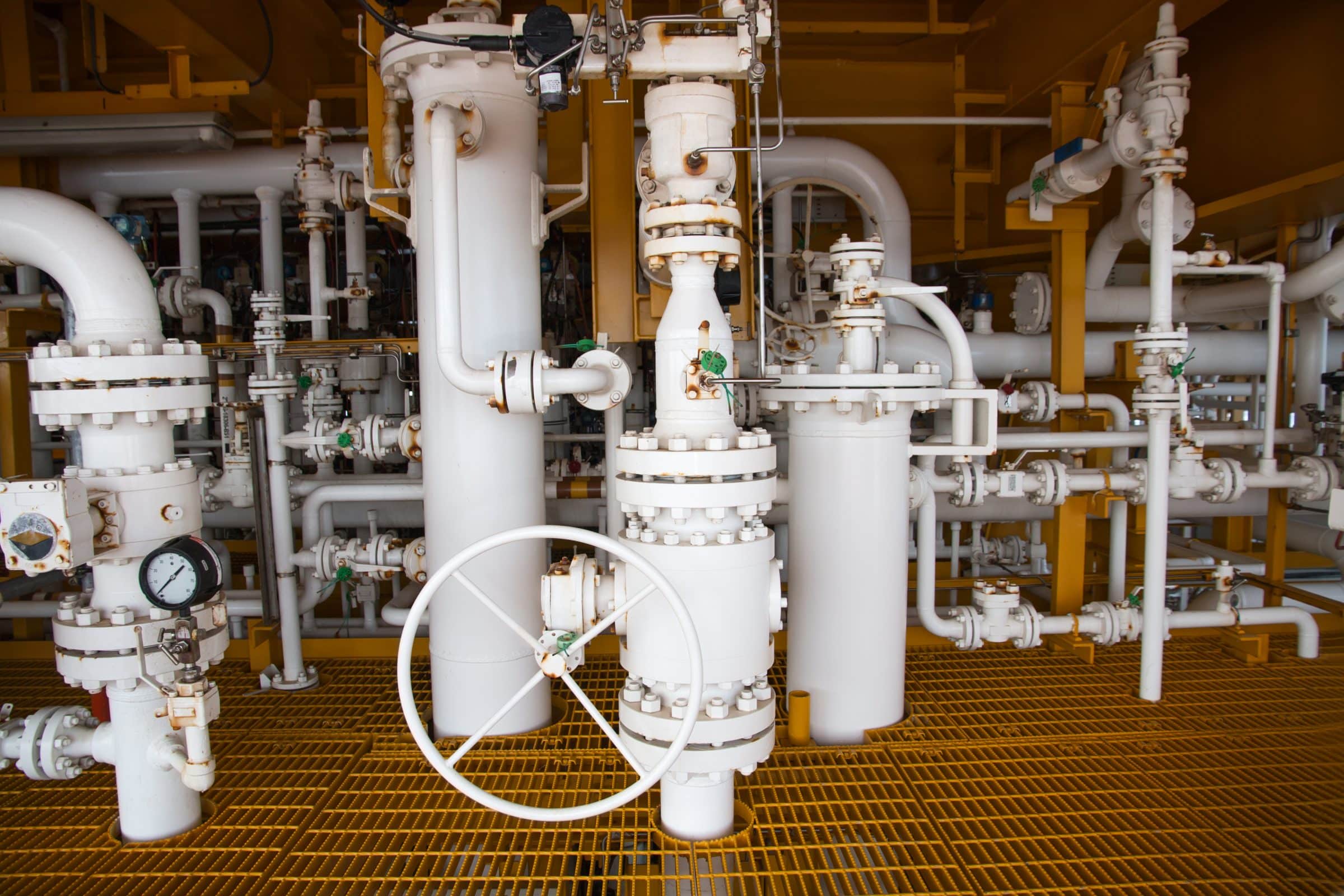

Traditional installations of Double Block & Bleed (DBB) valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges.

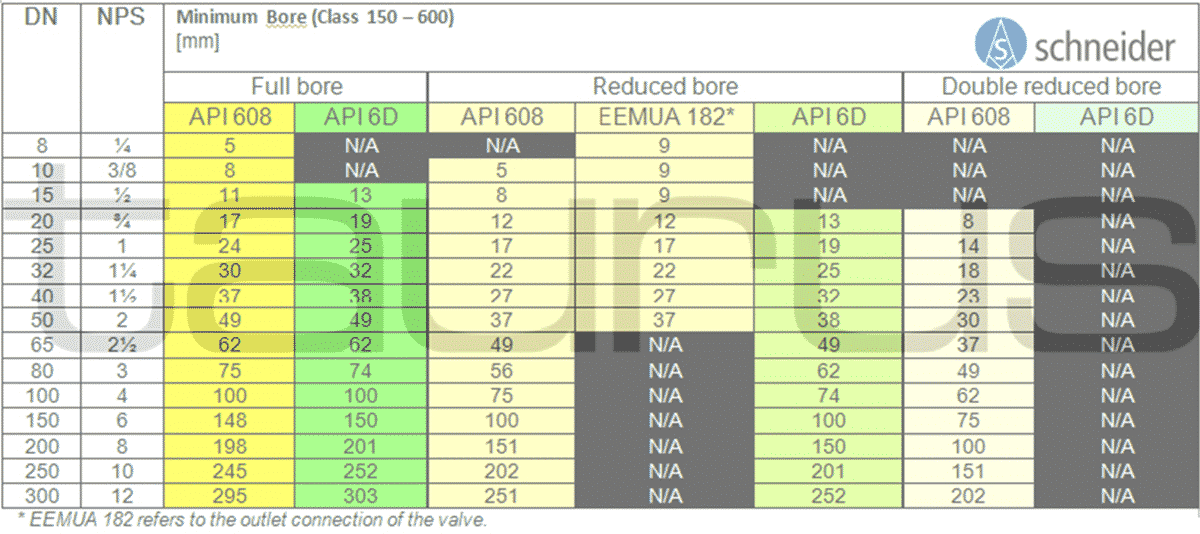

Continue readingWhat does Full Bore stand for?

There has always been a lot of confusion and misunderstanding when it comes to Full Bore and Reduced Bore terminology. Let me try to explain some interesting facts. For example, DBB Valves are developed mainly for the use in the Oil and Gas sector. In this industry, the relevant design standards are ….

Continue readingFugitive Emissions: ISO 15848 vs. TA-Luft

Tracking and limiting Fugitive Emissions has moved into the focus of many countries around the world. Stringent legal requirements force the industry to rethink and use emission-reducing equipment. This sounds very simple, but from my experience there is still misconception when it comes to this subject.

Continue reading