Welcome to the world of Modular Plant Systems. Construction of modularized plant system has become a popular choice of design. Especially in heavy process industries common to the Oil & Gas and Petrochemical Sector. Generally, such modularizations are used for compact steel frameworks commonly called “skids”. For example when equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted. A complete system may comprise a single skid or a number of skids to form a bigger and sophisticated processing system.

Continue readingSmart DBB Valve Technology

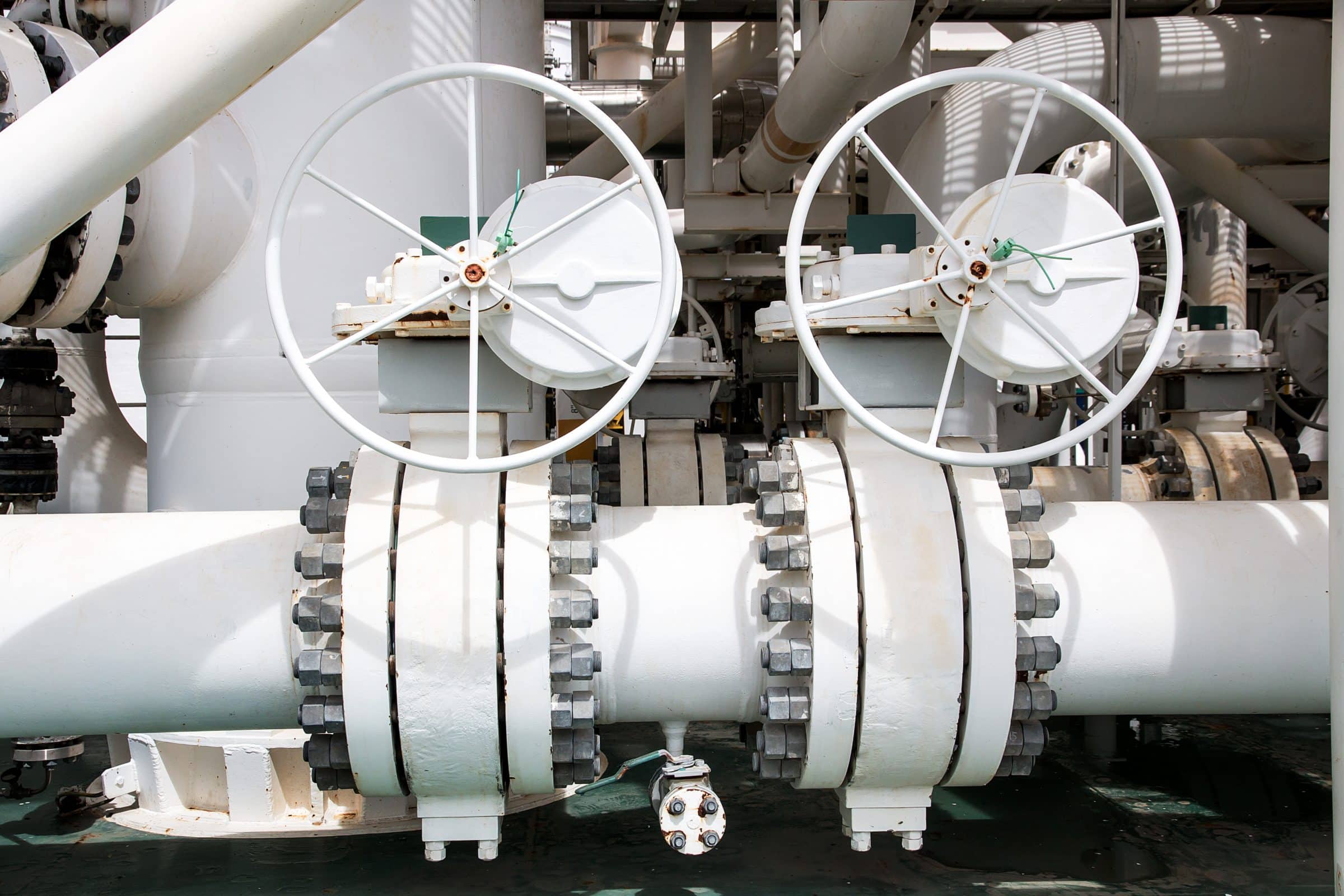

DBB Valves: Traditional installations of DBB Valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges. There are many steps to consider when completing the installation process. In total, there can be as many as 41 steps required for a traditional installation of DBB valves setup.

Continue readingCompact DDB Valves for Modular Plant Systems

Construction of modularized plant system has become a popular choice of design in heavy process industries like the Oil/Gas and Petrochemical Sector. Modularization is where equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted on a compact steel framework, commonly called “skids”.

Continue readingImportance of design flexibility for complex requirements

Valve customization is adapting to customers’ needs in regards to changing body materials, port connections, testing requirements, and various combinations of different assembly types. Being open to different design ideas, and accepting the challenge the customer set forth. As a valve manufacturer we strive to impress our customers with our many years of experience in building valves. Every day we continue to receive new design request from our customers for complex requirements. Since we have over 140 years in customizing valves experience, our customer can trust that we are experts in the industry.

Continue readingThe Advantantage of using a compact DBB Valve

In the Oil/Gas industry, although it has become very common, the use of a compact Double Block & Bleed (DBB) valve for pressure energy isolation is still not applied or adopted across the board. I have experienced a few times wherein the use of a DBB valve for process isolation is more of an option rather than a design requirement.

Continue readingCompact Double Block & Bleed vs. Conventional Installations

Double block and bleed valve systems are conventional installations for most End-Users in the Oil and Gas industry. Conventional installations of DBB valve systems have become a normal practice and can even be found on offshore platforms.

The installation of DBB valve systems is a time consuming process that can negatively impact employees and their work production. The normal process of this type is baded on:

Using two 6” 1500 class ball valve with all the additional materials,

Long and comlex installation process (up to a 41 steps)

Huge amount of material (weight of 2,645 lb(s) = 1200 kg

Cost Savings Through Better Performance during Installation and in Use

Traditional installations of Double Block & Bleed (DBB) valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges.

Continue reading