When I started my career as a valve engineer, one of the first lessons were: Which materials are used for valve components. Didn`t know too much about the details of the different materials, for me, the most strange material at that times was the 316 Series.

Continue readingThe Imperative of Fire Safe Testing!

I often hear people saying “Metal seated valves with graphite sealing don’t need to be fire safe tested, as all the components are fire resistant”.

To be honest, starting my career as a valve engineer, I was convinced, that this common understanding is true – until I did fire safe tests on my own for our Monoflange Series, many years ago. Even after this long period of time I remember very well, when we did the pre-tests. I looked very surprised, when the valve seat was leaking during the firing of the valve.

Important Facts about Fire Safe Standards

Reliable fire protection is essential for industrial valves in industries with sensitive applications. Because of the dangers that come within installations in the oil and gas, chemical, and petrochemical industries, the valves used must guarantee a reliable and safe shut-off in case of fire.

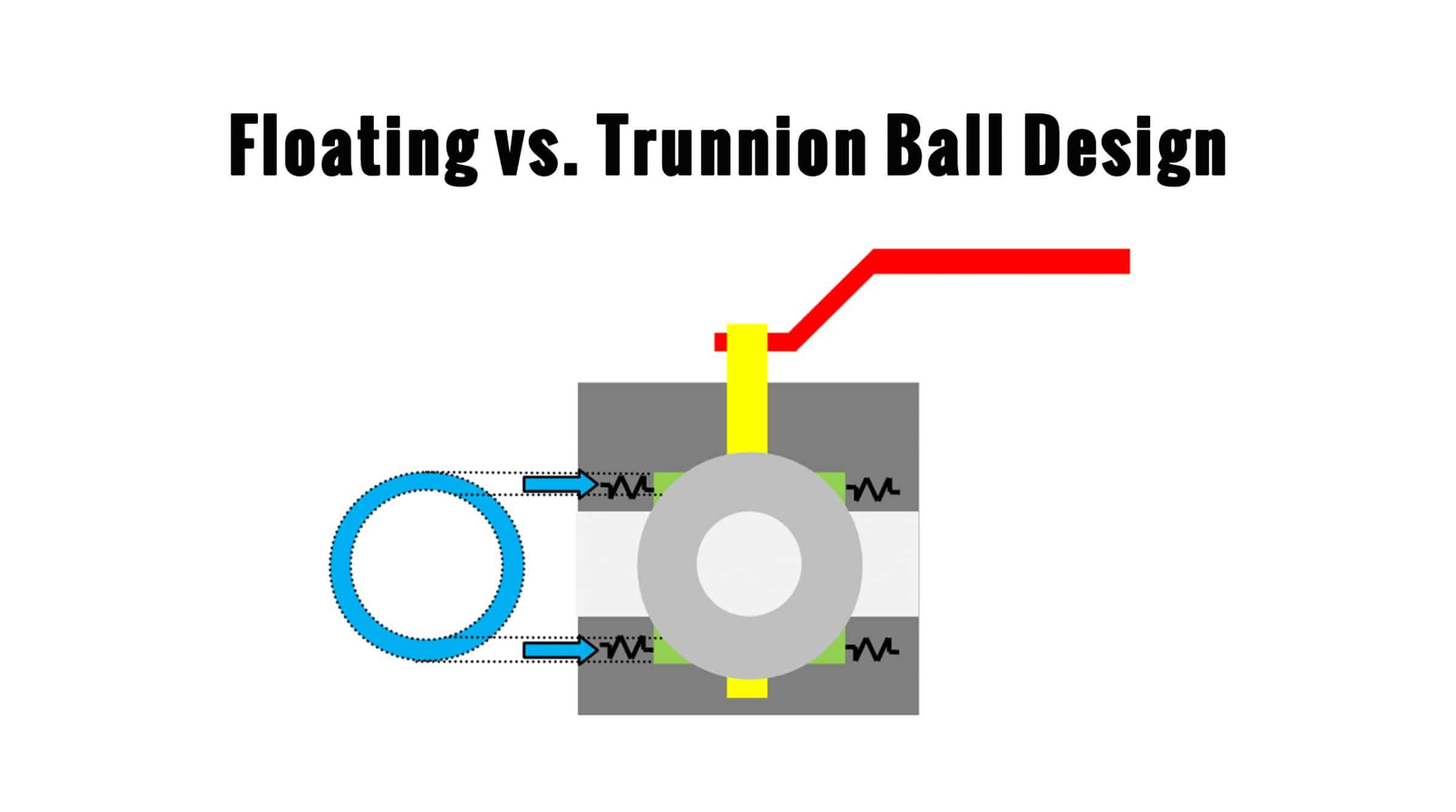

Continue readingDBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

Improve Safety – Upgrade to DBB Valves

It is very easy to upgrade your existing Single Isolate Ball Valve installation. Simply use a DBB with Face-to-Face and End-to-End dimensions acc. to ASME B16.10.

Use a DBB Dual Ball Design improve Safety and Process Reliability. Here is a simple infographic to illustrate the interchangeability using ASME B16.10 dimensions:

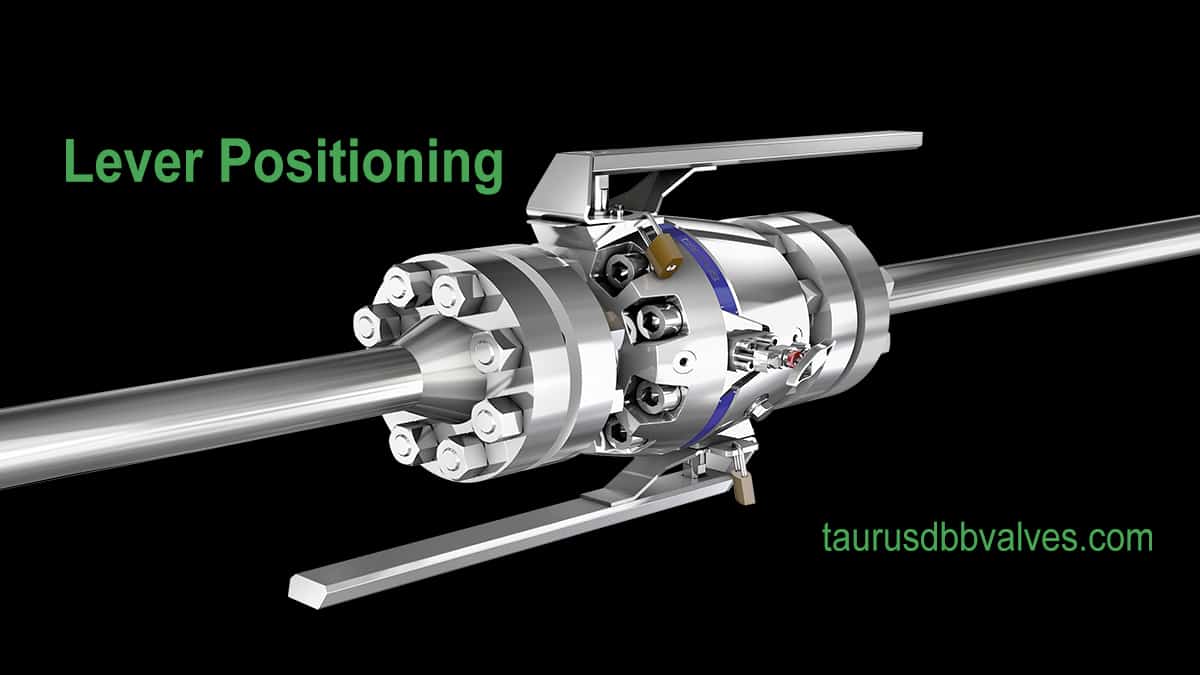

Continue readingHow the position of levers can influence the usability of DBB Valves

Several Ball Valve basic designs are common and therefore a lot of different solutions are available on the market. Especially the position / orientation of the levers have an enormous influence on the usability of the valve, when used in horizontal installations. The following pictures are showing two different options.

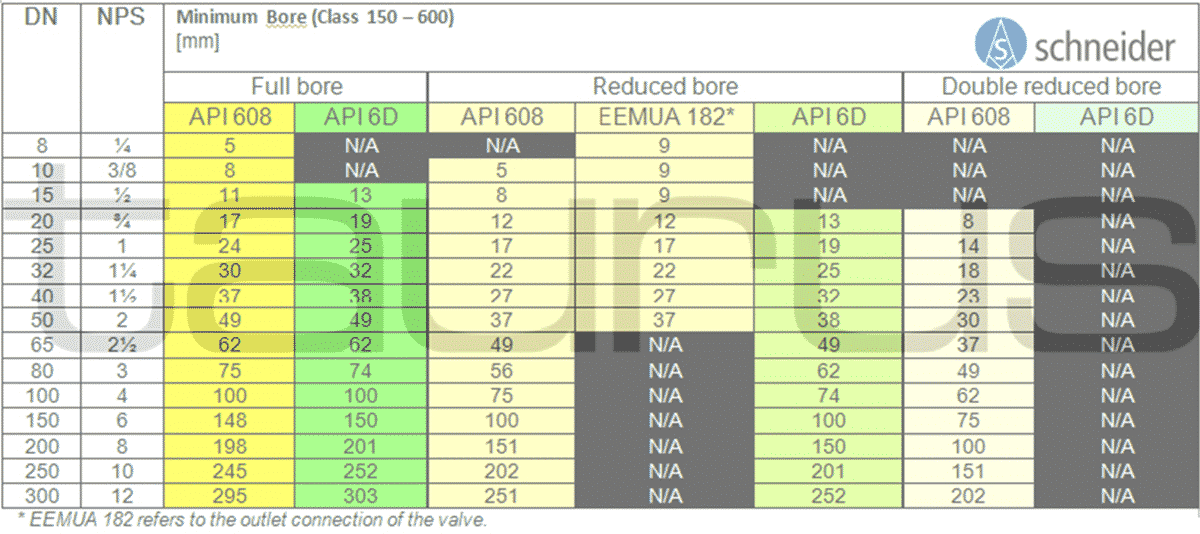

Continue readingWhat does Full Bore stand for?

There has always been a lot of confusion and misunderstanding when it comes to Full Bore and Reduced Bore terminology. Let me try to explain some interesting facts. For example, DBB Valves are developed mainly for the use in the Oil and Gas sector. In this industry, the relevant design standards are ….

Continue reading“Fire Safe Approved” vs. “Fire Safe by Design”

During the last years I recognized, that people sometimes talk about “Fire Safe by Design“. When I was coming across this the first time, I wondered about the meaning of this in detail – Just using metal to metal sealing, graphite sealing or graphite packing?

“Fire safe by Design” is widely used, but to my knowledge there is no common or firm description or rules limiting or qualifying the use of this concept.

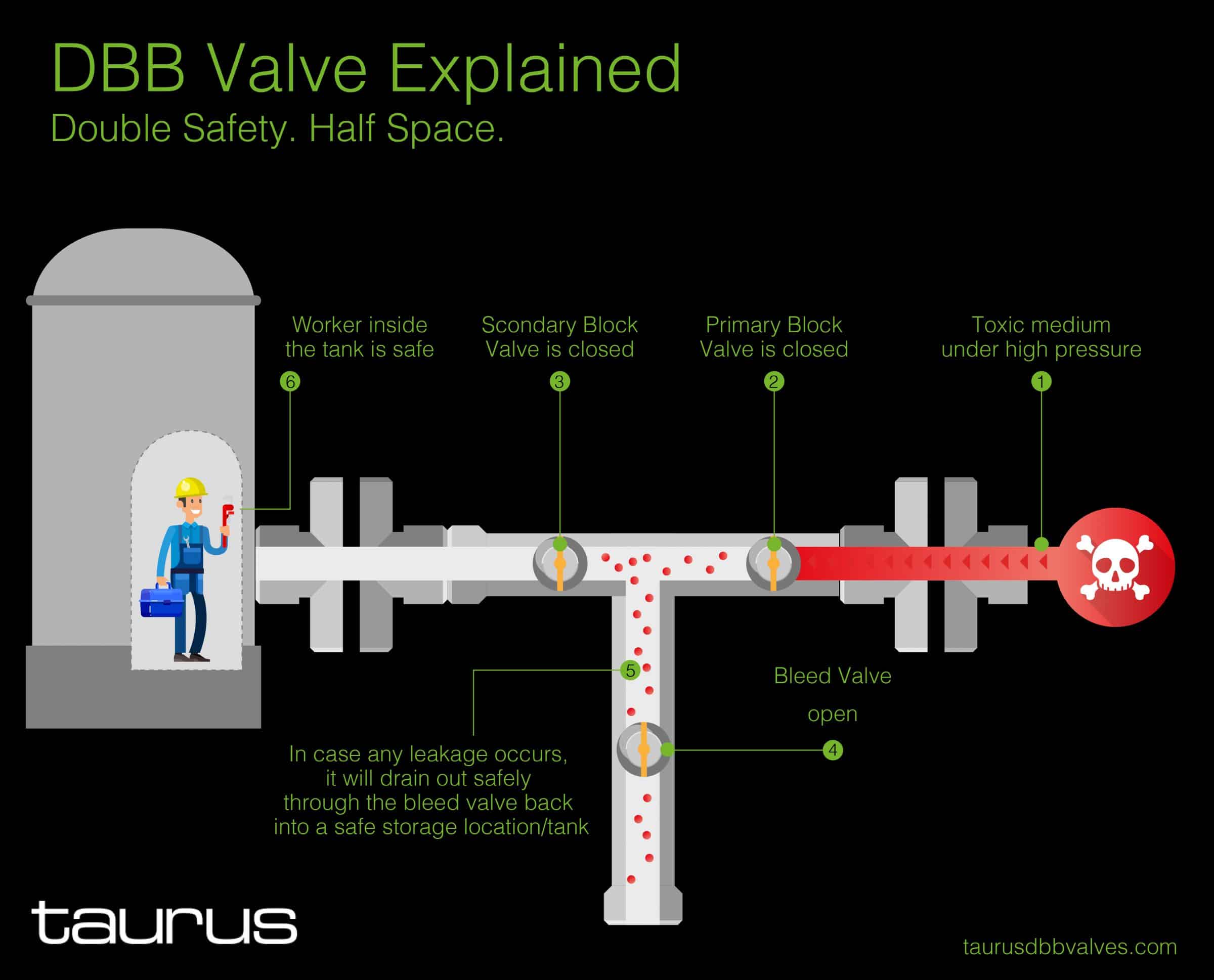

Continue readingDBB Valve Explained

I’m facing very often the situation where customers don’t understand the concept/purpose of the DBB functionality. Here is a simple infographic to explain one of the basic applications to protect the workers and the environment.

Continue reading