When considering the torque values to operate the valve, one must consider how much torque is required to fully open and fully close the valve. If the valve gets stuck in mid function of opening or closing the valve a safety factor must also be considered sizing the actuator.

Continue readingThe Paradoxon of Dual Certified Material 316 / 316L

When I started my career as a valve engineer, one of the first lessons were: Which materials are used for valve components. Didn`t know too much about the details of the different materials, for me, the most strange material at that times was the 316 Series.

Continue readingCompact DDB Valves for Modular Plant Systems

Construction of modularized plant system has become a popular choice of design in heavy process industries like the Oil/Gas and Petrochemical Sector. Modularization is where equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted on a compact steel framework, commonly called “skids”.

Continue readingImportance of design flexibility for complex requirements

Valve customization is adapting to customers’ needs in regards to changing body materials, port connections, testing requirements, and various combinations of different assembly types. Being open to different design ideas, and accepting the challenge the customer set forth. As a valve manufacturer we strive to impress our customers with our many years of experience in building valves. Every day we continue to receive new design request from our customers for complex requirements. Since we have over 140 years in customizing valves experience, our customer can trust that we are experts in the industry.

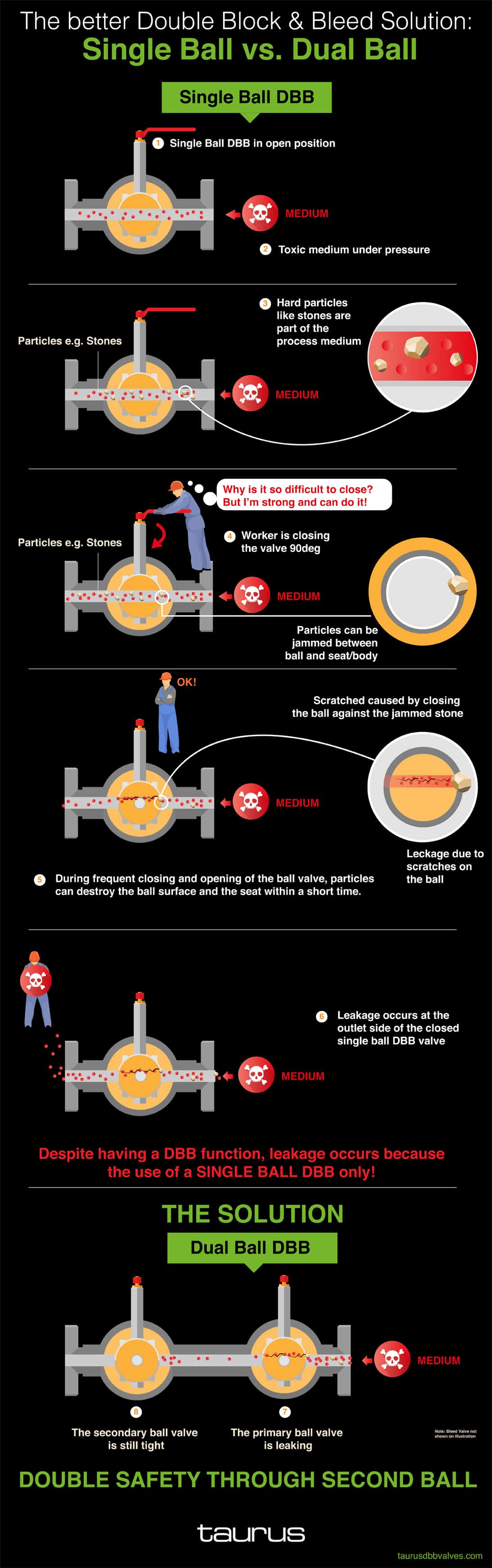

Continue readingSingle Ball DBB vs. Dual Ball DBB

Very often our sales people are being asked why to use a DBB Dual Ball Design and not just a Single Ball Design. A Single Ball Design would be much cheaper.

Well, the answer is very simple: Safety and Process Reliability.

Here is a simple infographic to explain the benefit of the Dual Ball Design.

Continue reading“Fire Safe Approved” vs. “Fire Safe by Design”

During the last years I recognized, that people sometimes talk about “Fire Safe by Design“. When I was coming across this the first time, I wondered about the meaning of this in detail – Just using metal to metal sealing, graphite sealing or graphite packing?

“Fire safe by Design” is widely used, but to my knowledge there is no common or firm description or rules limiting or qualifying the use of this concept.

Continue reading