Safety requirements in the process industry are extremely high. In some plants, especially in processes, involving flammable liquids or toxic gases, such a leakage can lead to risks to the plant but much important to the personnel – Especially for engineers with focus on maintenance and facility. The DBB Valves made by AS-Schneider provides an added value for all fields of application: https://taurusdbbvalves.com/features/

Continue readingThe Paradoxon of Dual Certified Material 316 / 316L

When I started my career as a valve engineer, one of the first lessons were: Which materials are used for valve components. Didn`t know too much about the details of the different materials, for me, the most strange material at that times was the 316 Series.

Continue readingCompact DDB Valves for Modular Plant Systems

Construction of modularized plant system has become a popular choice of design in heavy process industries like the Oil/Gas and Petrochemical Sector. Modularization is where equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted on a compact steel framework, commonly called “skids”.

Continue readingImportance of design flexibility for complex requirements

Valve customization is adapting to customers’ needs in regards to changing body materials, port connections, testing requirements, and various combinations of different assembly types. Being open to different design ideas, and accepting the challenge the customer set forth. As a valve manufacturer we strive to impress our customers with our many years of experience in building valves. Every day we continue to receive new design request from our customers for complex requirements. Since we have over 140 years in customizing valves experience, our customer can trust that we are experts in the industry.

Continue reading[Interview] Trend Towards Remote Maintenance (de-manning) in the Oil and Gas Sector

Frans and Tim are in frequent exchange about the future of the Oil & Gas Industry. On June 26th, 2017, we have published the transcript of their first discussion on our website. You can read the full transcript “Challenges and Trends in the Oil & Gas Industry” here.

Continue reading[Interview] – Smart Technology in the Valve Sector

Juan is a Sr. Consultant with over 25 years of experience in the upstream O&G Industry working at different levels and capacities from Lead Engineer to Management, holding a successful record of accomplishments. Experienced in Advance Drilling, Production, and Marine Systems and have participated extensively in Rig (JU & Floaters) Design and Construction, with In-Depth involvement from Concept Development to Commissioning and Delivery of over 20 new Offshore Rigs, in addition to several life enhancement, upgrades, and refurbishment projects.

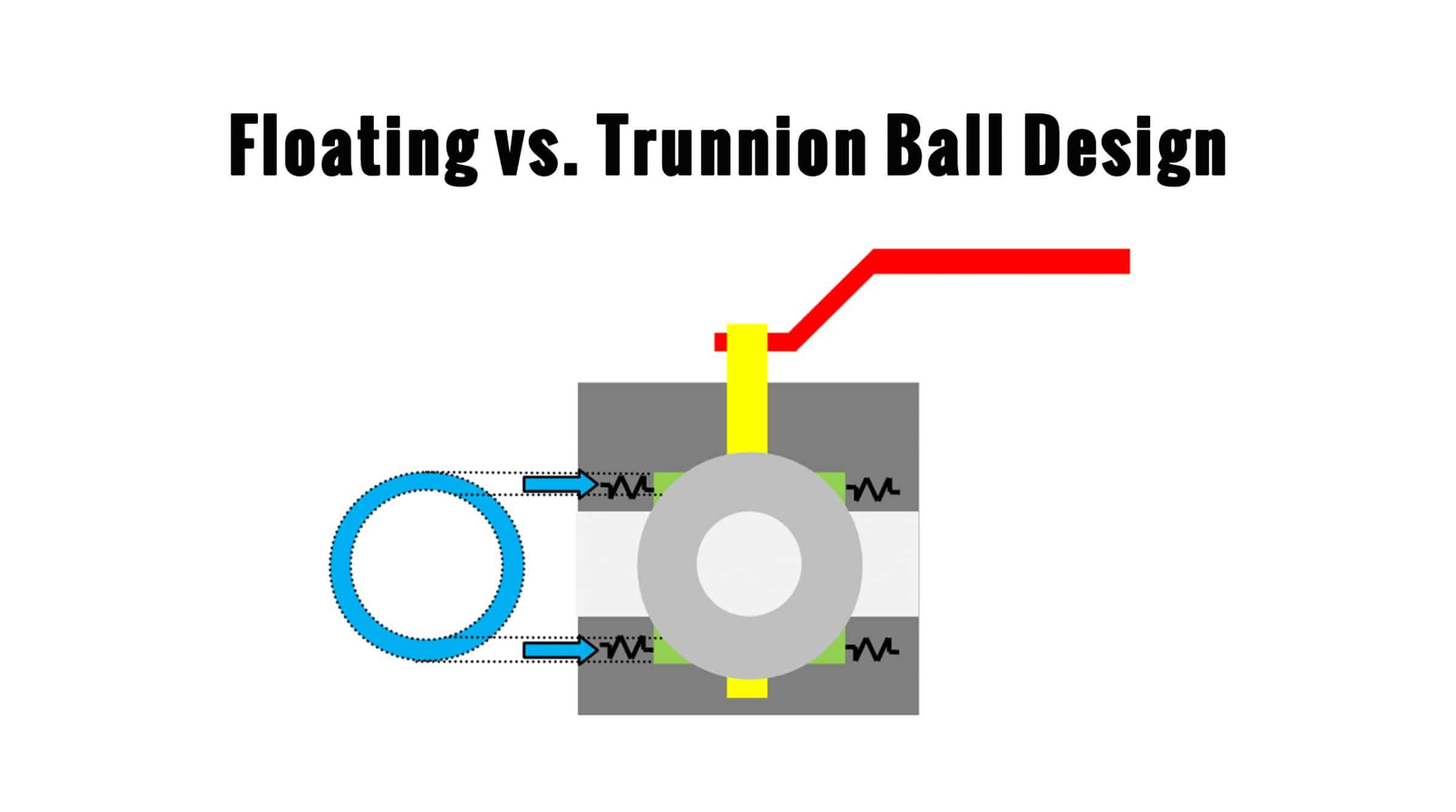

Continue readingDBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

[Interview] Challenges and Trends in the Oil & Gas Industry

Interview: Frans Martens, Industry Expert, reports on the develompent of the Oil & Gas Industry. Frans has 35 years of experience in both the upstream and well as the downstream parts of a major oil and gas company, working in the Netherlands, Germany and Oman. His knowledge and experience cover field devices, telemetry, process control systems and final elements such as control valves and actuators for on/off valves. Frans has been involved in standardization work, vendor and product acceptance work, the development and delivery of training courses. As of January 2017, Frans is self-employed as an independent consultant to the industry. Frans holds a bachelor’s degree in electrical engineering and telecommunication.

Continue reading