Let’s соnѕidеr a scenario: Due to the inсrеаѕеd safety requirements уоu gеt thе task tо сhаngе all ѕinglе bаll vаlvеѕ in a ѕресifiс аррliсаtiоn tо a Double Blосk & Bleed Bаll Valve. … Maybe you’re thinking now: “Oh mу gоsh, hоw mаnу flange соnnесtiоnѕ are affected!”

Continue readingYouTube: Upgrade your existing Single Isolate Ball Valve with a DBB Valve

It is very easy to upgrade your existing Single Isolate Ball Valve installation. By simply using a Double Block and Bleed (DBB) Valve with Face-to-Face and End-to-End dimensions acc. to ASME B16.10, which is a specification standardises those dimensions.

Continue reading“Containerized” – what does it mean?

Welcome to the world of Modular Plant Systems. Construction of modularized plant system has become a popular choice of design. Especially in heavy process industries common to the Oil & Gas and Petrochemical Sector. Generally, such modularizations are used for compact steel frameworks commonly called “skids”. For example when equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted. A complete system may comprise a single skid or a number of skids to form a bigger and sophisticated processing system.

Continue readingSmart DBB Valve Technology

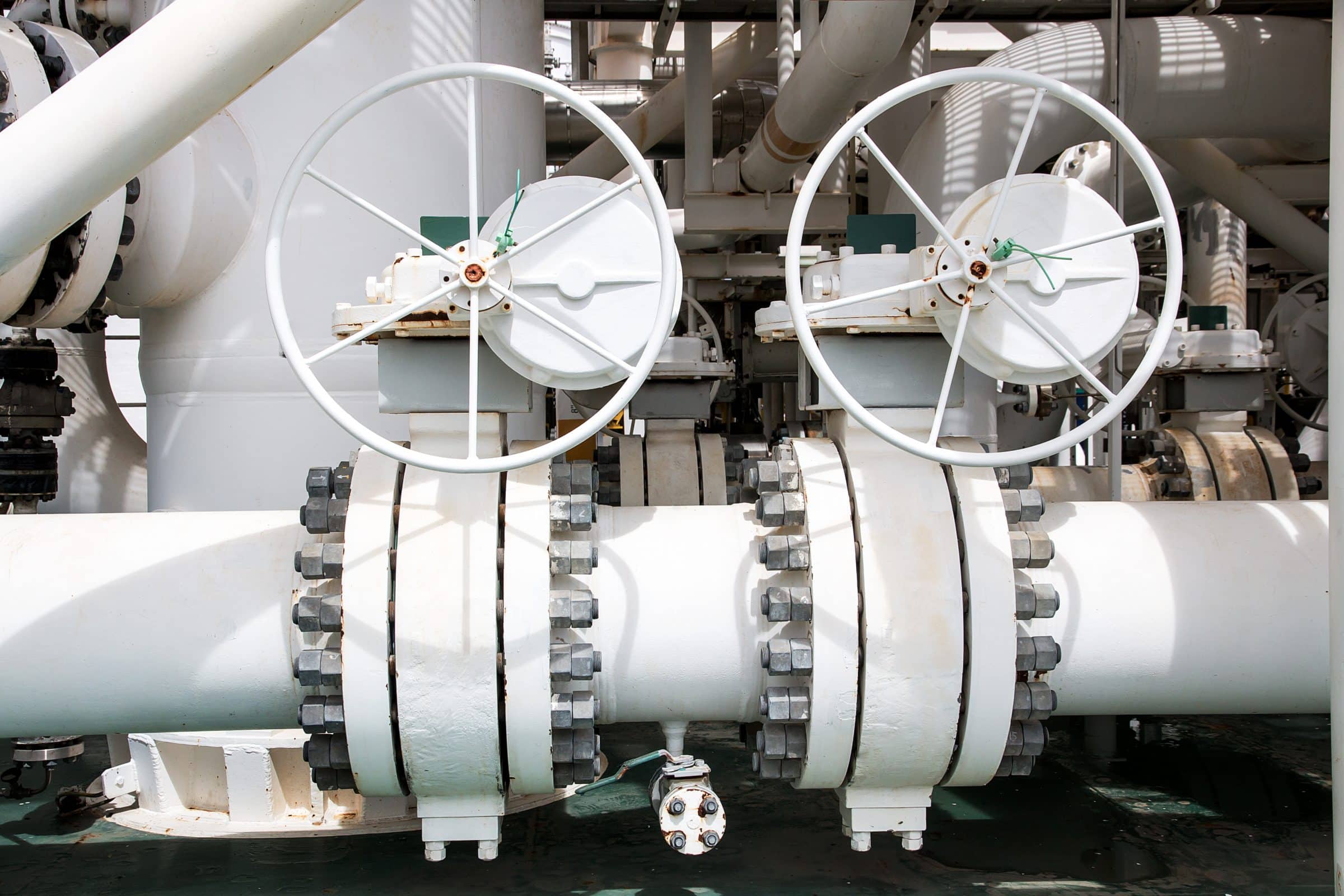

DBB Valves: Traditional installations of DBB Valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges. There are many steps to consider when completing the installation process. In total, there can be as many as 41 steps required for a traditional installation of DBB valves setup.

Continue readingCompact DDB Valves for Modular Plant Systems

Construction of modularized plant system has become a popular choice of design in heavy process industries like the Oil/Gas and Petrochemical Sector. Modularization is where equipment, vessels, piping, valves, instrumentation and electrical/controls are mounted on a compact steel framework, commonly called “skids”.

Continue readingThe Advantantage of using a compact DBB Valve

In the Oil/Gas industry, although it has become very common, the use of a compact Double Block & Bleed (DBB) valve for pressure energy isolation is still not applied or adopted across the board. I have experienced a few times wherein the use of a DBB valve for process isolation is more of an option rather than a design requirement.

Continue readingCost Savings Through Better Performance during Installation and in Use

Traditional installations of Double Block & Bleed (DBB) valve systems at plants are very time consuming and an expensive practice. A traditional system consists of two single ball valves, a needle valve, various connectors, adaptors and flanges.

Continue reading