It is very easy to upgrade your existing Single Isolate Ball Valve installation. By simply using a Double Block and Bleed (DBB) Valve with Face-to-Face and End-to-End dimensions acc. to ASME B16.10, which is a specification standardises those dimensions.

Continue readingHow to install a DBB Valve where a single isolation ball valve was previously installed?

For the most part, most engineers will start out by cutting the pipe in order to correct the dimension and weld new flanges on it. However, this daunting process can be avoided only if the DBB Valves conform to the ASME B16.10 End-to-End Dimensions. In other words, the DBB valves have to be manufactured or designed according to the ASME B16.10 Standard.

Continue readingInternational Standards that recognize and mandates the use of DBB Valves

Industry giants with the likes of Shell, Exxon, BP, Total and any major players for that matter, have rules and standard set in place dedicated to one subject area called Energy Isolation. Energy source could be in various form such as electrical, heat or pressure energy. Different companies and state agencies will have varying regulations and engineering practices for system or equipment isolation during maintenance and intervention. Nevertheless, regardless how minor or how critical the isolation requirement, the objective is to always meet the minimum “safety requirements”.

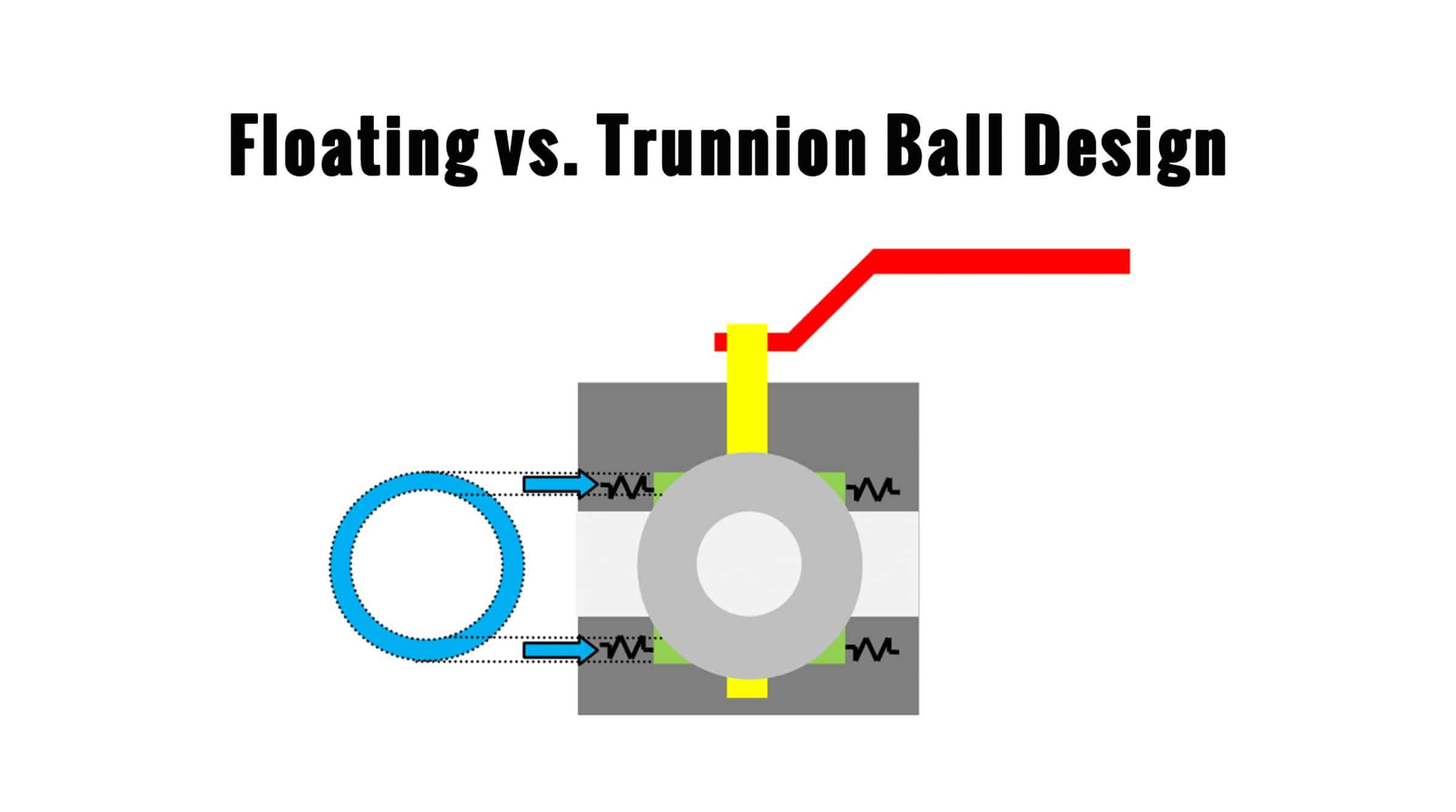

Continue readingDBB Valves: Floating vs. Trunnion Ball Design

The higher the pressure, the more the sealing elements are pressed together – and the higher are the forces on the ball and the seat.

This would not be a big problem, if the valve has not to be operated like a check valve. But a ball valve has to be operable, even under high differential pressure.

When high forces are acting on the sealing elements, the friction between them is high. This means that the operation torque and the wear on the parts are also high.

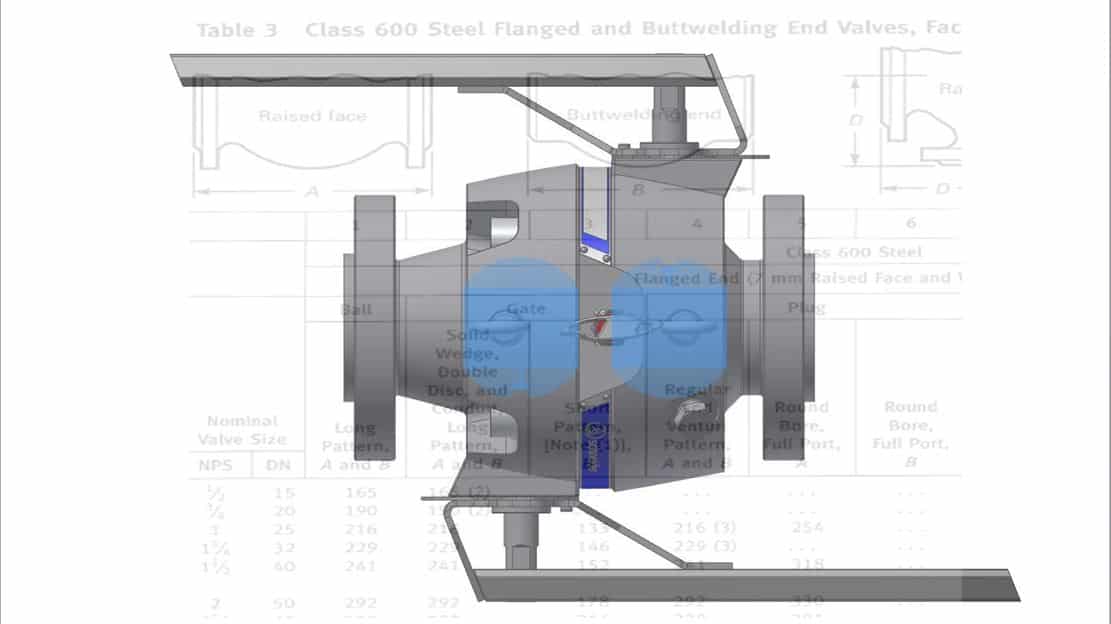

ASME B16.10 – Exploring why it matters to DBB Valves

Ever since 1922, ASME (American Society of Mechanical Engineers) has been defining pipeline safety upon demand from both industry and government. One of their standards has to do with face-to-face as well as end-to-end dimensions of straightway valves, centre-to-face and centre-to-end dimensions of angle valves. In this informative post, our primary focus will be on ASME B16.10 industrial valves.

Continue readingReplace a single ball valve by a Double Block & Bleed

When creating the design specification for our Taurus Series we came along the point ‘face to face’ dimensions. Immediately some colleague said “ASME B16.10 and EN 558 – but same length as a single ball valves for the Taurus DBB with 2 balls and a bleed in between?”

Well, we discussed that there might be a possibility to achieve this goal and we listed some values and benefits we could offer to our customers with such a short face to face dimension:

The major benefit would be that the new Double Block & Bleed (DBB) Pipeline Ball Valve (Taurus-Series) has the same face-to-face dimension as a single block ball valve. The length of a single block ball valve is specified in ASME B16.10 and APl 6D. As a consequence the valve can easily be installed into an existing pipeline without the need for any re-work on the pipeline.

Continue readingThe difference between Double Block & Bleed (DBB) and Double Isolate & Bleed (DIB)

Much confusion exists over the terminology and the differences between Double Block & Bleed Valves and Double Isolation & Bleed Valves. One point of confusion comes because many people using the term Double Block & Bleed really want a valve with Double Isolation & Bleed capabilities.

Continue reading