In the Oil/Gas industry, although it has become very common, the use of a compact Double Block & Bleed (DBB) valve for pressure energy isolation is still not applied or adopted across the board. I have experienced a few times wherein the use of a DBB valve for process isolation is more of an option rather than a design requirement.

Continue readingCompact Double Block & Bleed vs. Conventional Installations

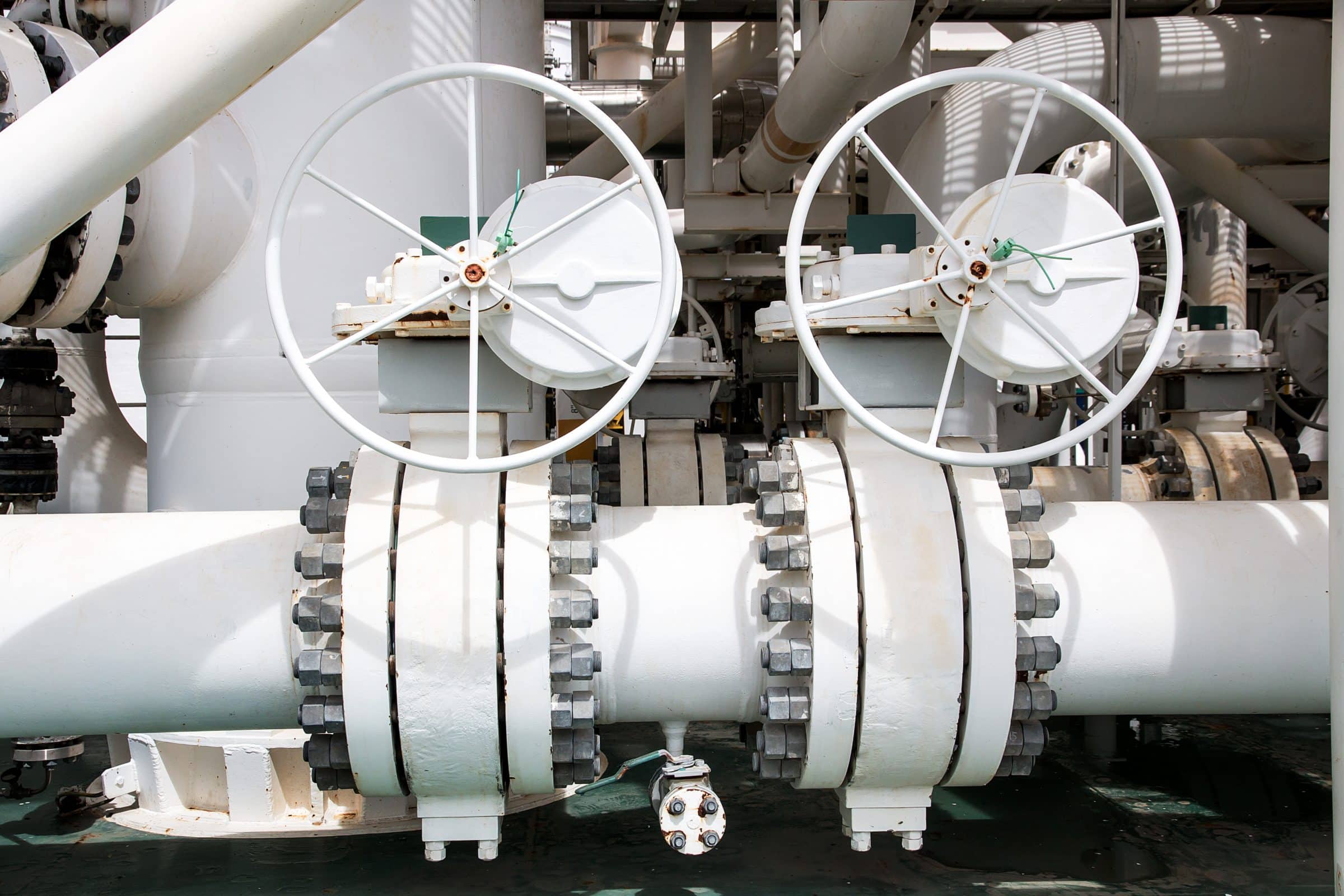

Double block and bleed valve systems are conventional installations for most End-Users in the Oil and Gas industry. Conventional installations of DBB valve systems have become a normal practice and can even be found on offshore platforms.

The installation of DBB valve systems is a time consuming process that can negatively impact employees and their work production. The normal process of this type is baded on:

Using two 6” 1500 class ball valve with all the additional materials,

Long and comlex installation process (up to a 41 steps)

Huge amount of material (weight of 2,645 lb(s) = 1200 kg