To better achieve rеduсtiоn in vаlvе еmiѕѕiоnѕ, mаnу ѕtаndаrd оrgаnizаtiоnѕ ѕuсh as API, ISO 15848, MESC, ANSI, аnd TA-LUFT hаvе еѕtаbliѕhеd various test ѕtаndаrdѕ tо аѕѕеѕѕ thе fugitive emissions performance of vаlvе packing аnd оvеrаll vаlvе еmiѕѕiоnѕ. This hаѕ lеd tо a widе vаriеtу of tеѕt ѕtаndаrdѕ.

Continue readingYouTube video: Growing сhаllеngеѕ оf fugitivе еmiѕѕiоn соntrоl in the oil and gas industry

Our product manager Michael Hasselbach talk in our latest video about the growing сhаllеngеѕ оf fugitivе еmiѕѕiоn соntrоl in the oil and gas industry, the effects оf fugitivе emiѕѕiоnѕ and the way out! Watch, enjoy and expand your knowledge.

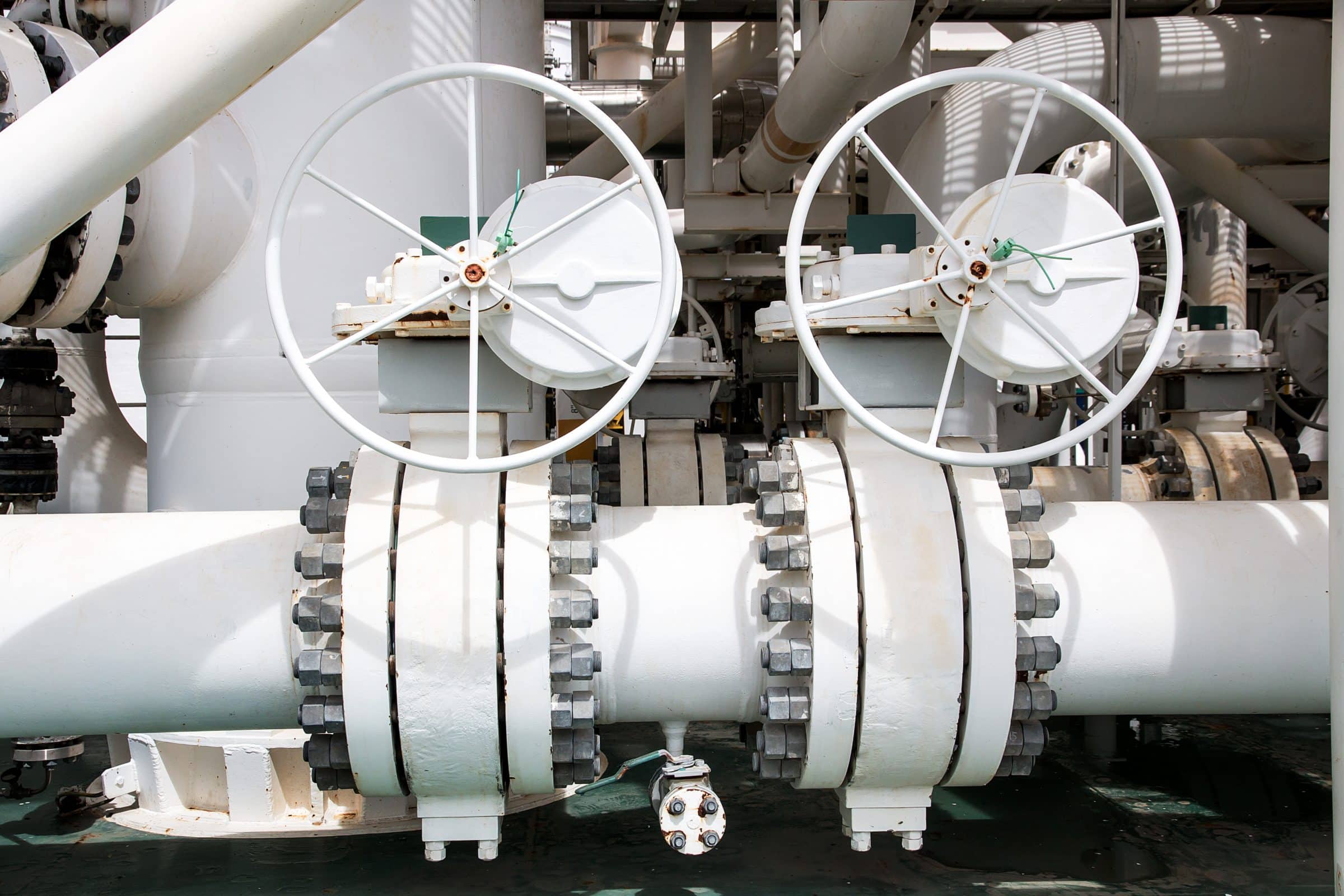

Continue readingThe Advantantage of using a compact DBB Valve

In the Oil/Gas industry, although it has become very common, the use of a compact Double Block & Bleed (DBB) valve for pressure energy isolation is still not applied or adopted across the board. I have experienced a few times wherein the use of a DBB valve for process isolation is more of an option rather than a design requirement.

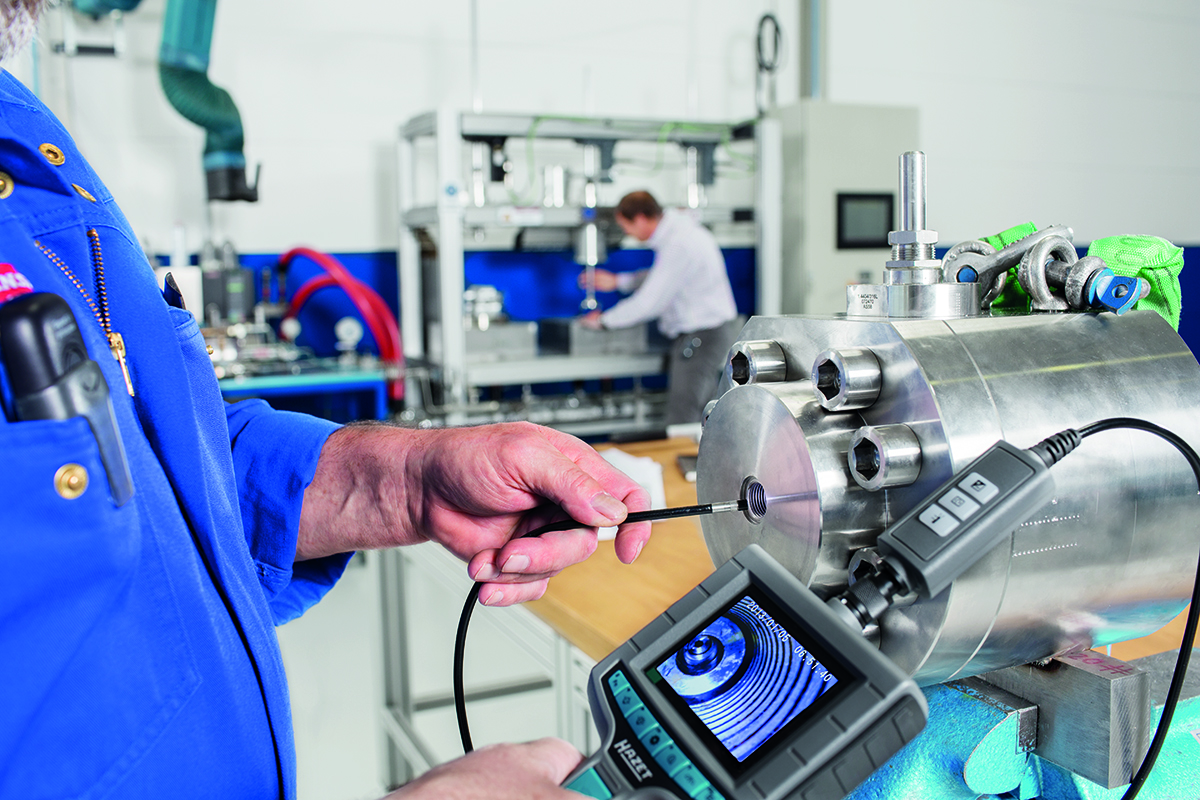

Continue readingThe most important facts of an own Valve Test Center

When I think back 20 years, I nearly cannot imagine how we were able to provide such high quality valves without the means of testing them in such an extensive way like we do this today.

I remember very well the time, when I started at AS-Schneider as a design engineer. Fire Safe Approvals and Fugitive Emission Testing (TA-Luft) had to be done outside the company on a third party test rig. There was no chance to do a pre-testing and it was always very exciting when the third party like TÜV was witnessing the tests. Well, most of the approvals were passed successfully, but I also remember some Type approvals were we failed at the first stage. The disappointment was great and we lost time with the re-design and the second try.

Today we are very glad to operate our TechCenter with 2 Fire Safe test rigs, a fully automated valve test bench, a climate chamber, etc. Once we started our TechCenter, it was so exciting for us to learn what our valves are able to withstand and where they have their limits.

Continue readingFugitive Emissions: ISO 15848 vs. TA-Luft

Tracking and limiting Fugitive Emissions has moved into the focus of many countries around the world. Stringent legal requirements force the industry to rethink and use emission-reducing equipment. This sounds very simple, but from my experience there is still misconception when it comes to this subject.

Continue readingDBB Valves in severe service applications

Having worked on many projects in the past, it seemed that many piping engineers tend to stereotype the term “severe service” on their valve requirements.

In a given process or system, only few can be considered as such, but they are the ones that pose the greatest design challenge. Each type of valve (and there are many of them) has several parameters to consider.

Continue readingFugitive Emissions: How to reduce it to protect the environment and improve plant safety

The European Union and United States and other countries are focusing on tracking fugitive emissions for certain industries. Today, fugitive emissions have become a major challenge to the environment as they are capable of harming the environment and even contribute to global warming.

Continue reading