International Standards that recognize and mandates the use of DBB Valves

Industry giants like Shell, Exxon, BP or Total have rules and standards set in place dedicated to one subject area called Energy Isolation. Energy source could be in various form such as electrical, heat or pressure energy.

Different companies and state agencies have varying regulations and engineering practices for system or equipment isolation during maintenance and intervention. Nevertheless, regardless how minor or how critical the isolation requirement, the aim is to meet the minimum “safety requirements”.

In this article, I would like to discuss about the types of valve isolations. And also to show the standards that mandate the use of a Double Block and Bleed Valve (DBB) to achieve a positive isolation. It is easy to conceive that many major players may have patterned their safety regulations and standards from these big names in the industry, down to the topic of valve isolations.

So these questions are occasionally asked: When and where do we use Single Block Valve, Single Block and Bleed Valve (SBB) and Double Block and Bleed Valve (DBB)? Are there international standards or regulations that mandates which type of valve isolation to be used?

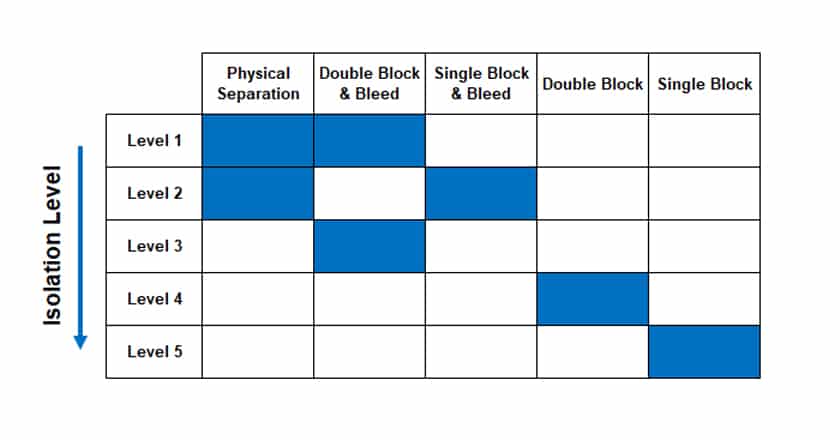

The answer to these questions lies on the different isolation levels and the types of valve isolation. Simply put, a certain type of valve can only meet a certain level of isolation. One particular standard that is less discussed but gives a good overview and guideline about all these is the NORSOK P-001. Below is its classification and summary.

Levels of Isolation (NORSOK P-001) for DBB Valves

OSHA Standards for DBB Valves

Depending who interprets its statement, Federal Occupational Health and Safety Association (heading: #OSHA) also recognize the use of Double Block & Bleed Valves (DBB) as a means of isolation similar to physical separation. Quoting from OSHA:

Isolation means the process by which a permit space is removed from service and completely protected against the release of energy and material into the space by such means as: blanking or blinding; misaligning or removing sections of lines, pipes, or ducts; a double block and bleed system; lockout or tagout of all sources of energy; or blocking or disconnecting all mechanical linkages.

OSHA

(Image source: © Ainoa/Fotolia & AS-Schneider)