How the position of levers can influence the usability of DBB Valves

Several Ball Valve basic designs are common and therefore a lot of different solutions are available on the market. Especially the position / orientation of the levers have an enormous influence on the usability of the valve, when used in horizontal installations. The following pictures are showing two different options.

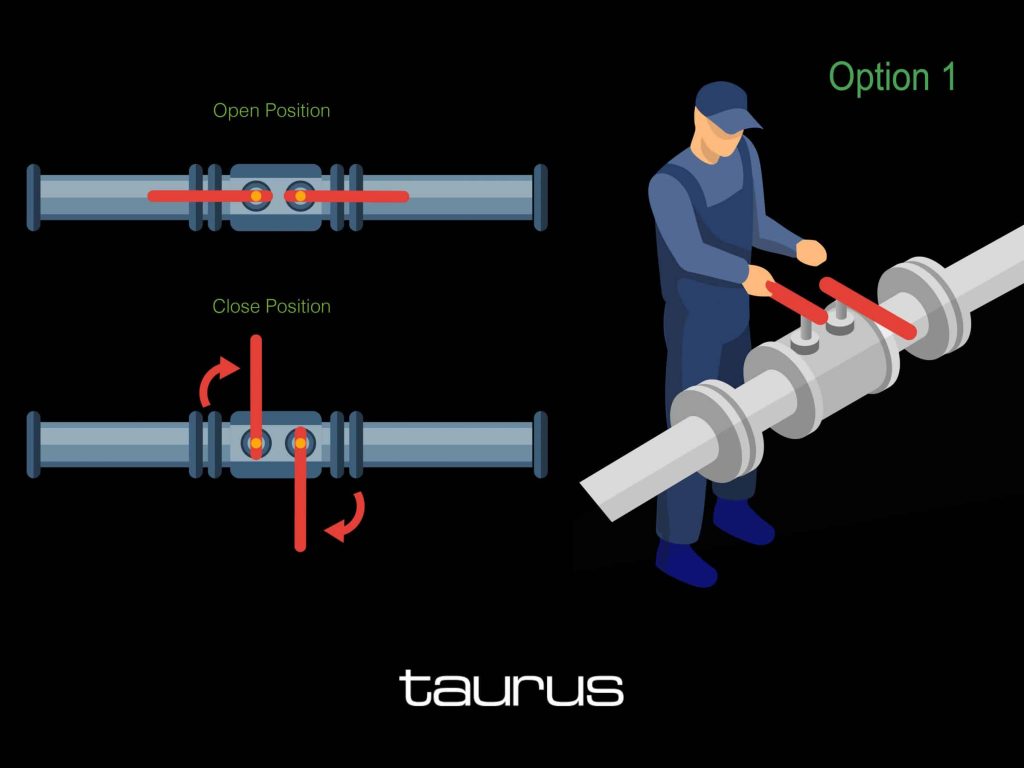

Option 1 – Valve open

The levers are located on the same side but facing to opposite directions.

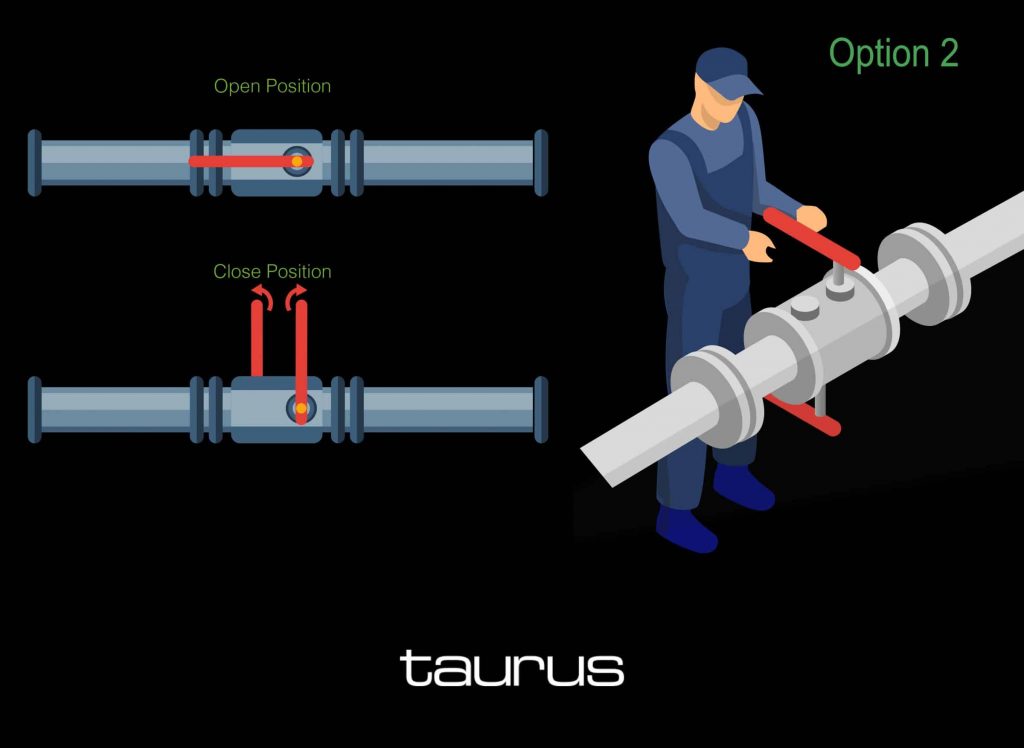

Option 2 – Valve open

But when closing the 2 valves there is a tremendous difference between the 2 options. The accessibility of option 2 is much better because the levers are oriented towards the operators’. Result: Ease of handling and safer handling. In contrast to option 1, the levers are facing to different directions.

Additionally, a lot of applications require a discharge pipe connected to the vent connection. In these cases the best way is to use a valve like option 2 with a positioned vent connection on the opposite side of the operators’ location. So a discharge pipe can be installed at the vent connection and it does not effect and trouble the person who has to operate the valve.

This example illustrates that it is important to understand the designs, the difference and the consequence for the user to ensure the highest safety level. Especially in process plants where space is limited it is important that even in the FEED stage all these basic requirements are considered.

Note: According to all common specifications and regulations the lever of a ball valve needs to be operated clockwise, when closing the valve.

(Images source: © AS-Schneider)