What does Full Bore stand for?

‘Full Bore’ / ‘Reduced Bore’ – Some Interesting Facts

There has always been a lot of confusion and misunderstanding when it comes to Full Bore and Reduced Bore terminology. Let me try to explain some interesting facts.

For example, DBB Valves are developed mainly for the use in the Oil and Gas sector. In this industry, the relevant design standards are:

- API 6D / ISO 14313

Petroleum and natural gas industries — Pipeline transportation systems — Pipeline valves

- API 608 / ISO 17292

Metal ball valves for petroleum, petrochemical and allied industries

- EEMUA 182

Specification for integral block and bleed valve manifolds for direct connection to

The ‘Full Bore’ requirement

Definition acc. to API 6D / ISO 14313:

“Full-opening valve: Valve with an unobstructed opening, not smaller than the internal bore of the end connections”

Here the ‘Full Bore’ requirement is very clear, as the respective standards give information about the bore size for each pipe size.

The key points are:

- Although API 6D and API 608 are published by the same organization, there are slight differences regarding the bore size requirements.

- API 608 is limited to pressure classes 150 to 600, therefore we decided to use API 6D which also gives rules for pressure classes up to 2500.

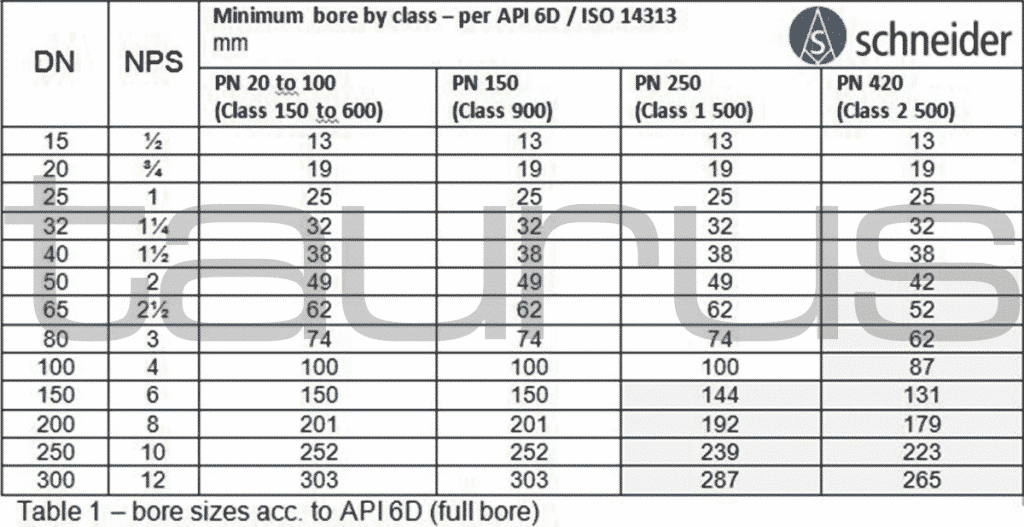

- Depending on the pressure class, the minimum bore size in API 6D is slightly reduced, starting with DN 50 / NPS 2 (see table 1 below)

I would like to point out, that some manufacturers – for some sizes – do smaller bore sizes as defined in API 6D. Maybe for technical reasons as the bore size effects the forces on the valve seat in an exponential effect (quadratic influence). Nevertheless, it is important to fulfill the API 6D by 100% to comply to the standard.Table 1 – bore sizes acc. to API 6D (full bore)

The ‘Reduced Bore’ requirement

Definition acc. to API 6D / ISO 14313:

“Reduced-opening valve: Valve with the opening through the obturator smaller than that of the end connection(s) … one size below nominal size of valve with full bore opening (for valves DN 300 / NPS 12 and below).”

Definition in EEMUA 182 (for ball valves)

- “No flow passage shall be smaller than 9mm;

- Outlet connection larger than DN20 (NPS ¾): ISO 17292 reduced bore.”

Whereas the ‘Full Bore’ requirement is very clear, the ‘reduced bore’ requirement is raising some questions, especially for smaller pipe sizes which are used for primary isolation valves for instrument piping.

The key points are:

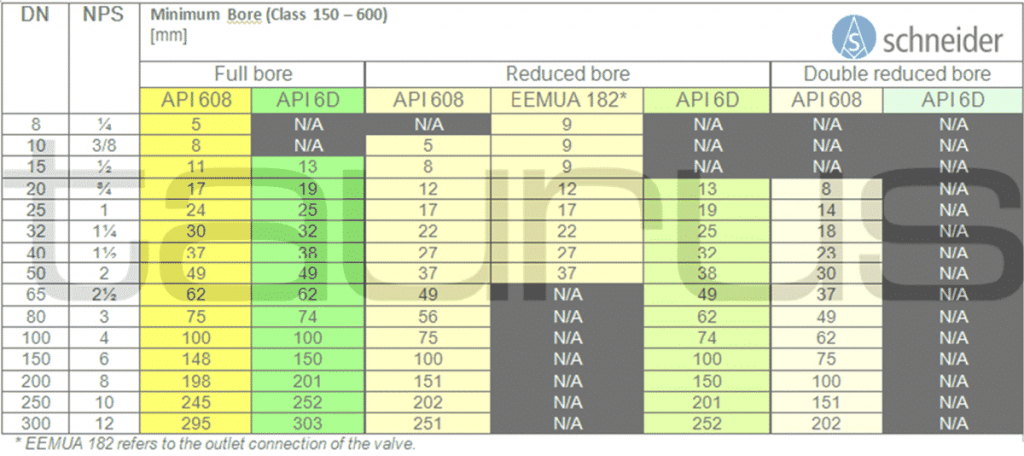

- API 6D defines ‘reduced bore’ valves, whereas API 608 also describes ‘double reduced bore’ valves

- Some people talk about reduced bore without referring to a describing standard. In this case, it is very important to clarify the minimum bore size with the customer so that he gets what he wants.

- There is a gap in EEMUA 182 for valves with ratings greater than class 600

The gap in EEMUA 182

EEMUA 182 refers to ISO 17292 (API 608) regarding the bore size. But the scope of ISO 17292 is limited to class 150 – 600 (for flanged end valves).

So what about the classes 900 to 2500?

In this case also a clarification with the customer is necessary for offering the correct valve.

From my experience in standardization work, it’s not easy to publish a standard that is 100% error-free. Members of such working groups are usually very busy in their company and have only limited time to check the standards. They are also dependent on the users of the standard, who should give their feedback regarding possible errors or gaps ……. just thinking about writing to EEMUA ;- )

Summary

In my opinion you always have to be aware of the ruling standard when talking about ‘full bore’ or ‘reduced bore’ valves, as there are small differences in the different specifications.

The following table shows a comparison between API 6D, API 608 and EEMUA 182 for pressure classes 150-600.

Note: EEMUA 182 refers to the outlet connection of the valve.

(Image source: © AS-Schneider)