Compact Double Block & Bleed vs. Conventional Installations

Facts about the Conventional Installation

Double block and bleed valve systems are conventional installations for most End-Users in the Oil and Gas industry. Conventional installations of DBB valve systems have become a normal practice and can even be found on offshore platforms.

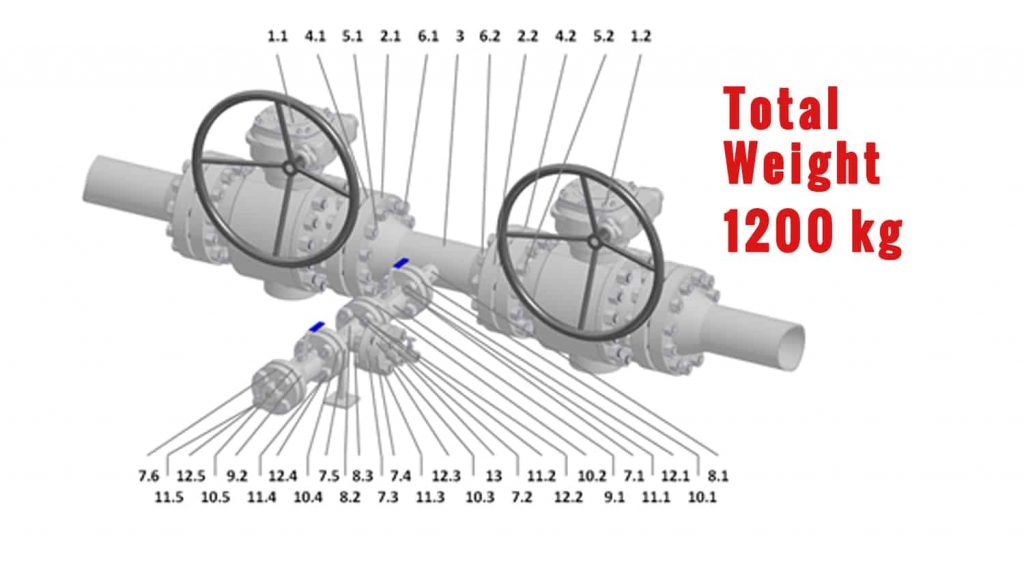

The installation of DBB valve systems is a time consuming process that can negatively impact employees and their work production. The normal process of this type is baded on:

- Using two 6” 1500 class ball valve with all the additional materials,

- Long and comlex installation process (up to a 41 steps)

- Huge amount of material (weight of 2,645 lb(s) = 1200 kg)

Pros of the Compact Double Block & Bleed Valve solution

In comparison, a prefered method is to use a Compact DBB Valve and not doing a conventional installation with individual valves.

Instead of using two valves in the earlier example, Compact Double Block & Bleed Valves only requires one single valve. This results in:

- Reduced weight (down to 2,094 lb(s) = 950 kg) –> If the end-user has 10 different DBB valve installations, using Compact DBB Valves would eliminate over 20,000 extra pounds of weight

- Increasing profits because of minimized shut down time

- Highest safety with maximizing customer profits

(Images source: © Sergey Ilin/Fotolia, Alexander Potapov/Fotolia)