The Paradoxon of Dual Certified Material 316 / 316L

When I started my career as a valve engineer, one of the first lessons were: Which materials are used for valve components. Didn`t know too much about the details of the different materials, for me, the most strange material at that times was the 316 Series.

At AS-Schneider all material specifications call for quadruple certification as standard (1.4401 / 1.4404 / 316 / 316L, acc. to EN10272 and ASTM A479 for bar material, respectively EN10222-5 and ASTM A182 for forged material).

Since the material 316 is actually identical to 1.4401 and 316L is identical to 1.4404, I will continue to write only 316 and 316L, always meaning both of them.

The difference between 316 and 316L

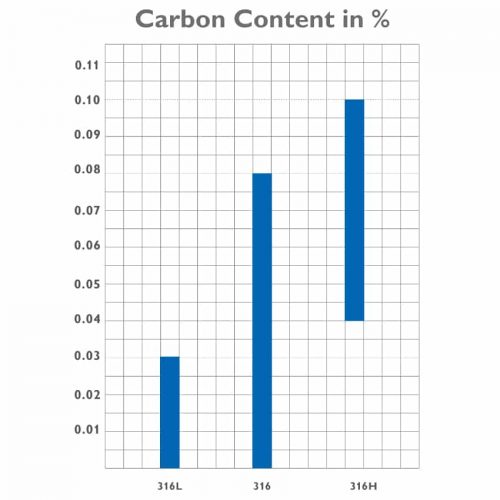

316L Stainless Steel has less Carbon in it than 316. This is easy to remember, as the L stands for “low”. Cost wise they are very similar, and both have a good corrosion resistance.

For projects that require a lot of welding, you better choose the 316L grade. It is slightly more weldable than the grade 316, due to its lower carbon content. 316L is also more resistant to intergranular corrosion.

So far so good! But we have to look not only at the material specifications, but also at standards like ASME B16.34. Here we find further differences in the pressure and temperature range the materials can be used. So it’s not just the carbon content.

The table below shows the main differences of 316, 316L (“Low Carbon”) and 316H (“High Carbon”) grades.

| ASTM A479 / ASTM A182 | ASTM A479 / ASTM A182 | ASTM A479 / ASTM A182 | ASME B16.34 | ASME B16.34 | ASME B16.34 | 316L | max. 0.03% | 485 MPa | 170 MPa | 2.3 | 450°C | 344.7 bar |

|---|---|---|---|---|---|---|

| 316 | max. 0.08% | 515 MPa | 205 MPa | 2.2 |

538°C when Carbon content < 0.04% |

413.7 bar |

| 316 | max. 0.08% | 515 MPa | 205 MPa | 2.2 |

816°C when Carbon content ≥ 0.04% |

413.7 bar |

| 316H | 0.04 – 0.10% | 515 MPa | 205 MPa | 2.2 | 816°C | 413.7 bar |

Note: For 316H grade, there are additional requirements regarding the grain size.

ASME B16.34 “Valves Flanged, Threaded and Welding End” is one of the most important standards for industrial valves worldwide. As you can see, the 316L is limited in the maximum allowable pressure and temperature.

Until here, all this is understandable and logical. Nevertheless as a valve manufacturer I have to ask myself the following question:

“If almost all 316 Series materials in the world are dual certified, why do we still need both materials 316 and 316L?” With the dual certification, we can achieve all the advantages of both grades.

Imagine: You manufacture a valve of a dual certified 316/316L material. And only depending on how you name the material (“316” or “316L”), the valve will have different max. allowable working pressures and temperatures – isn’t that scary?

Markus Häffner

Summary

The paradoxon is caused by the missing lower limit for the carbon content of the material 316.

As the carbon content influences the maximum allowable working temperature and also the strength of the material, there should be a lower limit for the 316 grade. Instead of “max. 0.08%”, this could be “0.03 – 0.08%”. Then all the differences in the pressure and temperature ratings would be justified.

But adding such a lower carbon content limit would have big economic consequences to the industry (stock-keeping, availability, costs, modification of uncountable documents).

(Image source: © Fotolia / Maksym Yemelyanov & AS-Schneider)