-

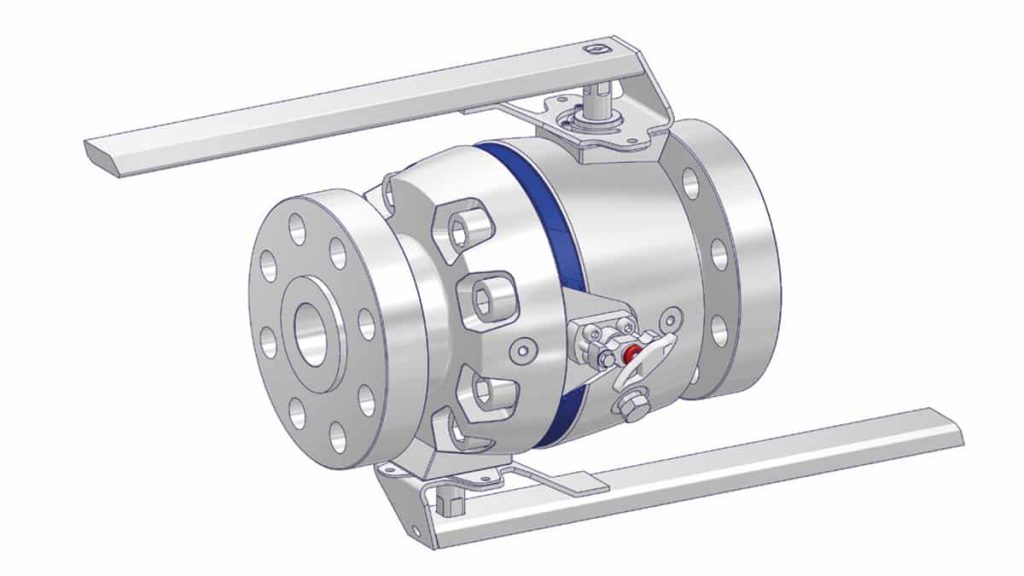

DBB full bore valves

Meets the minimum bore

requirements according to API 6D / ISO

14313, Table 1. -

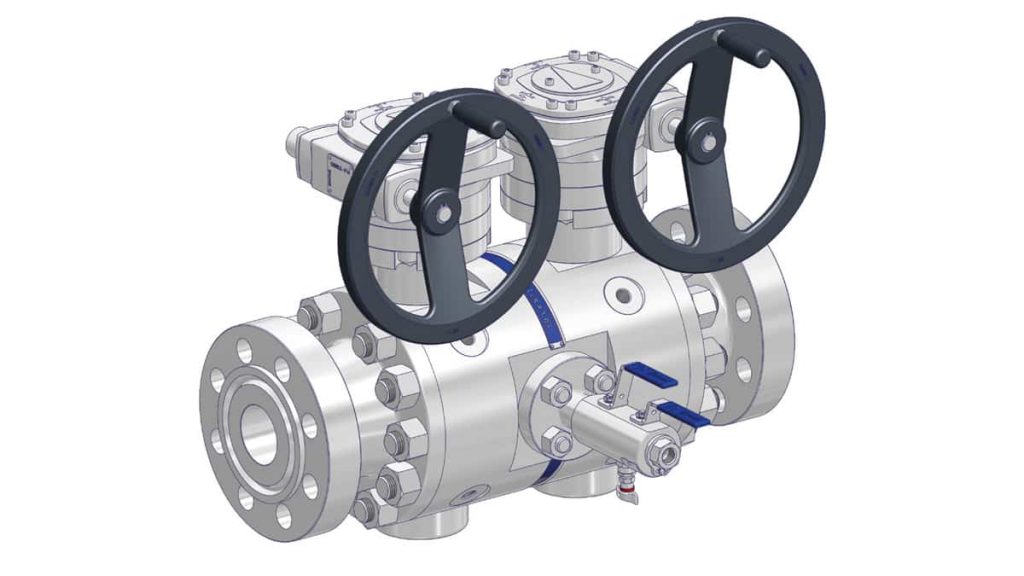

DBB reduced bore valves

One size below nominal size of valve

with bore according to API 6D / ISO

14313, Table 1. -

Pressure

Meets pressure class from 150 to

2,500.

-

Fire safety solution

Fire safe in acc. to API 607 and ISO

10497 -

Compliant to NACE

NACE MR0175 and ISO 15156 -

Factory test

Factory tested in acc. with ASME B16.34, API 6D / ISO 14313, ISO 5208 -

Manufacturing

In acc. with the pressure equipment

directive (PED)